How to Test and Validate a Wiring Harness

Why Testing Matters

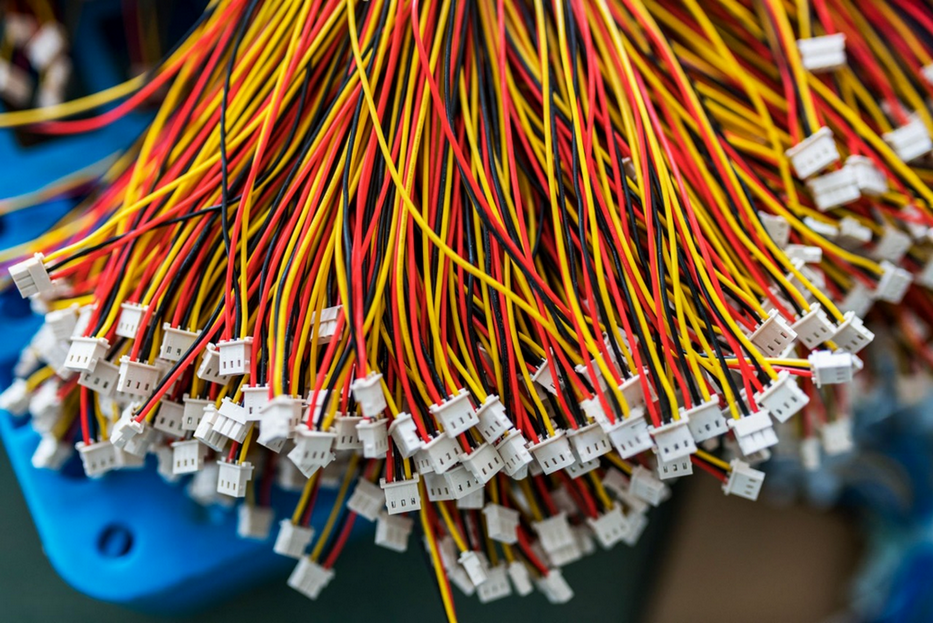

In custom wire harness manufacturing, testing is not optional but essential. Whether powering a smart refrigerator, a robotic assembly line, or an electric vehicle, the wiring harness is the foundation of safe, reliable performance. At Celestix Industries India Pvt Ltd, we recognize the stakes. That’s why every harness we manufacture undergoes 100% inspection, guided by industry-best standards and tailored testing procedures.

From electrical continuity to environmental resilience, our validation process is engineered to meet your specifications and exceed expectations. Our reputation as a trusted wiring harness manufacturer is built on this commitment.

Beyond functionality, testing ensures long-term durability and compliance with regulatory and OEM-specific standards. Whether it's EMI resistance for telecom applications, biocompatibility for medical devices, or fast-charging compatibility for electric vehicles, testing converts design into dependable reality.

This is the essence of wiring harness testing—ensuring your product performs consistently and safely in real-world conditions. When your project requires validated performance, Celestix delivers.

Our End-to-End Testing & Validation Protocols

We follow a rigorous test process to confirm electrical integrity, mechanical strength, and environmental durability. This comprehensive wire harness validation guide is your roadmap to reliability.

1. Continuity Testing

Purpose: Confirms complete, uninterrupted electrical pathways

Equipment: CAMI Research CableEye, in-line testers

Detects open circuits, short circuits, and miswiring

Real-time diagnostics for efficient quality control

Standard: IPC/WHMA-A-620 Class 3

Validates schematic integrity and detects wiring errors before they reach production

2. High-Voltage (Hi-Pot) Testing

Purpose: Verifies insulation performance under electrical stress

Voltage Range: Up to 5,000V AC/DC, depending on application

Simulates high-voltage stress to ensure no dielectric failure

Detects insulation breakdown that may not appear during normal use

Mandatory for all high-voltage EV harnesses and aerospace builds

Compliant with UL, IEC 60228, and ISO 6722 standards

3. Pull-Force Testing

Purpose: Evaluates mechanical strength of crimped and connected joints

Unit of Measure: Newtons (N)

Validates secure terminal crimps and ensures no dislodgement under stress

Key to verifying strain relief in dynamic environments such as automotive or machinery

Every crimp is validated to exceed customer-specific force thresholds

4. Crimp Cross-Section Analysis

Purpose: Microscopic verification of crimp quality

Tools: Precision sectioning tools, microscopy, digital analyzers

Ensures proper material deformation for low resistance contact

Identifies voids, bird-caging, or insufficient crimp depth

Analysis is logged for traceability and included in PPAP submissions

Conducted after each tooling setup or any tooling anomaly

5. Environmental Stress Testing (When Required)

Thermal Cycling: Validated between -40°C and +125°C to simulate seasonal extremes

Salt Fog and Humidity: Corrosion resistance for marine and coastal applications

Vibration Testing: In accordance with IEC 60068, replicating real-world motion stress

Abrasion Resistance: Verifies jacket and sleeve integrity under physical wear

Ingress Protection (IP): Tested up to IP67/IP68 for sealed over-molded connectors

Environmental harness testing is particularly critical for defense, renewable energy, and high-durability machinery applications.

6. Visual and Label Inspection

Purpose: Verifies visual conformity and traceability

Conducted By: IPC-certified inspectors

Confirms connector orientation, pinouts, label positioning, and color coding

Barcode checks for traceability across production batches

Ensures aesthetic quality as well as correct component integration

First-pass visual inspection is followed by secondary QA sign-off

7. Functional Testing (Customer-Specific)

Signal Integrity: Measured across data lines, CAN bus, or sensor interfaces

Connector Fitment: Measured insertion and retention force values using test fixtures

Live System Simulation: Harness integration into mock control panels for operational checks

Simulation setups mirror final field application environments, improving test relevance

Functional harness validation ensures system-level performance and interface compatibility, especially critical in applications involving multiple control modules or third-party components.

Tooling and Automation

To ensure consistent and reliable outcomes, Celestix invests in high-end testing infrastructure:

Multimeters for continuity diagnostics

Hi-pot testers for insulation breakdown checks

Automated test platforms with report generation

Custom-configured wire harness test benches

In-house test jig development tailored to customer drawings

Automation accelerates testing throughput while eliminating human error in repetitive validations. Our digital logging system also ensures complete test traceability for audits and compliance.

Specialized Testing for Key Industries

We provide tailored validation for high-performance sectors:

Automotive harness testing for thermal, vibration, and EMI resilience

EV wiring harness validation focused on high-voltage safety and fast-charging efficiency

Aerospace harness validation using lightweight materials and IP-rated components

Appliance harness testing for energy efficiency and moisture resistance

Industrial harness test guides for control panels, PLCs, and robotics environments

We support full PPAP packages, First Article submissions, and Engineering Change control. Our validation programs are customizable for end-product requirements, launch timelines, and regional certifications.

Certifications That Set Us Apart

Celestix’s quality control is aligned with global and regional standards:

ISO 9001:2015, IATF 16949:2016, ISO 45001:2018

UL, CE, RoHS, REACH, ISO 14001

BIS-compliant testing for Indian regulatory requirements

IPC/WHMA-A-620, J-STD-001 testing standards

We ensure compliance documentation, test logs, and material declarations are available for every shipment.

What You Receive with Every Shipment

Every Celestix harness includes a robust documentation and validation package:

Certificate of Conformance (COC)

Full continuity, high-voltage, and mechanical test records

Material safety and RoHS/REACH compliance statements

Product labeling and traceability reports

CAD drawings or wiring diagrams upon request

All testing data can be archived electronically or integrated into your QA system.

Why Choose Celestix for Harness Validation

Every conductor, terminal, and crimp point is verified to the highest standard. At Celestix, testing is not a checkpoint—it’s a philosophy. We combine extensive engineering knowledge with precision validation systems to deliver products that are truly production-ready.

Your application demands more than functionality—it demands assurance. From high-voltage reliability to EMI protection and environmental resilience, we engineer certainty into every wire harness.

To begin your next validated wiring project, fill out our contact form or email the Celestix team today.

Ensure Performance. Prove Reliability. Deliver with Confidence.