Automotive Wiring Harness

At Celestix Industries, we believe that wiring is more than a utility—it’s the nervous system of every vehicle. As a dedicated automotive wiring harness manufacturer, our mission is to engineer connections that drive safety, performance, and innovation across every platform, from legacy ICE vehicles to next-generation EVs and autonomous systems. We don’t just supply car wiring harnesses; we provide end-to-end engineering support that helps OEMs and Tier 1 suppliers bring complex vehicle programs to life with precision and scalability.

Headquartered in Pune, India, and trusted by global B2B customers, Celestix delivers custom automotive harness solutions built for consistency under the toughest conditions. Whether it’s battery management in EVs, sensor integration for ADAS, infotainment wiring for connected vehicles, or engine control for hybrid powertrains, we ensure that every wire, connector, and overmold is optimized for durability, compliance, and real-world performance. With expertise spanning automotive, aerospace, medical, renewable energy, and industrial IoT, we bring cross-industry innovation into every program.

What We Build: Platform-Driven Wiring Systems

Celestix designs and manufactures custom automotive wire assemblies for:

EV wiring harnesses for battery management, charging, propulsion, and high-voltage systems

ICE wiring harnesses for engine control, transmission, fuel injection, and emission reduction

ADAS harnesses supporting LiDAR, radar, vision clusters, and collision avoidance systems

Infotainment & dashboard harnesses for navigation, telematics, HMI, and climate control

Lighting harnesses for DRLs, adaptive headlights, ambient lighting, and fog lamps

Hybrid vehicle harnesses balancing dual energy management and efficiency

Motorcycle & commercial vehicle harnesses for rugged, vibration-heavy environments

Harness designs incorporate:

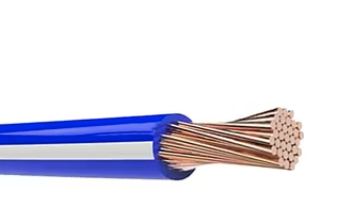

Copper and aluminum conductors (ISO 6722, TXL, FLRY, AVSS)

Flame-retardant overmolds in silicone, polyethylene, ABS

EMI shielding and strain relief for signal integrity and durability

Lightweight routing strategies for compact, space-constrained builds

How We Work: Engineering-First Manufacturing

Our automotive harness design approach focuses on early validation and production scalability:

ECAD/3D modeling & DFM optimization for seamless vehicle integration

Rapid prototyping with functional harness samples delivered in <7 days

Automated crimping, ultrasonic welding, and precision overmolding

Full PPAP, APQP, FMEA, and batch-level traceability

Certified compliance with IATF 16949, UL, BIS, RoHS, and REACH

Assembly to IPC/WHMA-A-620 and J-STD-001 standards

This ensures reduced rework, accelerated launches, and production-ready builds with consistent quality.

Application-Specific Automotive Wiring Solutions

Celestix harnesses are engineered for critical automotive functions:

EV harnesses for propulsion, charging ports, and high-voltage battery systems

Hybrid harnesses for powertrain coordination and dual energy routing

ADAS harnesses for autonomous driving, parking assist, and lane-departure systems

Lighting harnesses for adaptive beams, DRLs, and full-vehicle lighting systems

Infotainment harnesses powering connectivity, HMI, and entertainment clusters

Engine harnesses for ICE efficiency, emissions, and combustion management

Transmission & drivetrain harnesses for clutch-by-wire and gearshift systems

Brake system harnesses for ABS, traction control, and e-brakes

Interior harnesses for power seats, heating, cooling, and lumbar support

High-voltage automotive harnesses for EV, hybrid, and heavy-duty vehicles

CAN bus harnesses for modular control and secure communication

Multi-Sector Expertise Beyond Automotive

Beyond automotive, Celestix provides custom wire harnesses for:

Aerospace (thermal extremes, EMI protection, vibration resistance)

Medical devices (biocompatibility, precision routing)

Industrial equipment (abrasion resistance, multi-core sheathing)

Renewable energy (solar inverters, batteries, smart grids)

IoT & telecom (data centers, network hardware, factory automation)

Testing, Safety & Compliance

Every automotive wiring harness is validated against rigorous benchmarks:

Continuity testing for flow integrity

Insulation resistance testing for long-term safety

Hipot testing for dielectric breakdown validation

Mechanical durability tests (vibration, pull force, abrasion resistance)

Thermal resistance tests for high-heat environments

Environmental exposure tests for fluid, salt, and humidity

All builds comply with ISO 9001, IATF 16949, ISO 14001, ISO 45001, CE, BIS, RoHS, and REACH standards with complete traceability.

Why OEMs & Procurement Teams Choose Celestix

Fast RFQ turnaround with working samples in under 1 week

Supply chain optimization with risk-mitigated sourcing

Full traceability & compliance documentation

Scalable production from prototype to SOP

Tailored automotive harness solutions for ICE, hybrid, EV, and ADAS platforms

Celestix is more than a supplier—we’re a long-term engineering and sourcing partner that integrates seamlessly into OEM workflows.

Let’s Engineer Confidence

At Celestix, every harness is built with the same commitment: to engineer reliability into every connection. From EV wiring harness development to ICE legacy platforms, from ADAS integration to connected vehicle systems, we deliver solutions that scale with confidence.

Submit your RFQ, request a design review, or connect with our team today.

Celestix — Engineering Confidence Into Every Connection.