Cable Harness Standards: The Engineer’s Guide to Quality, Compliance, and Reliability

Introduction

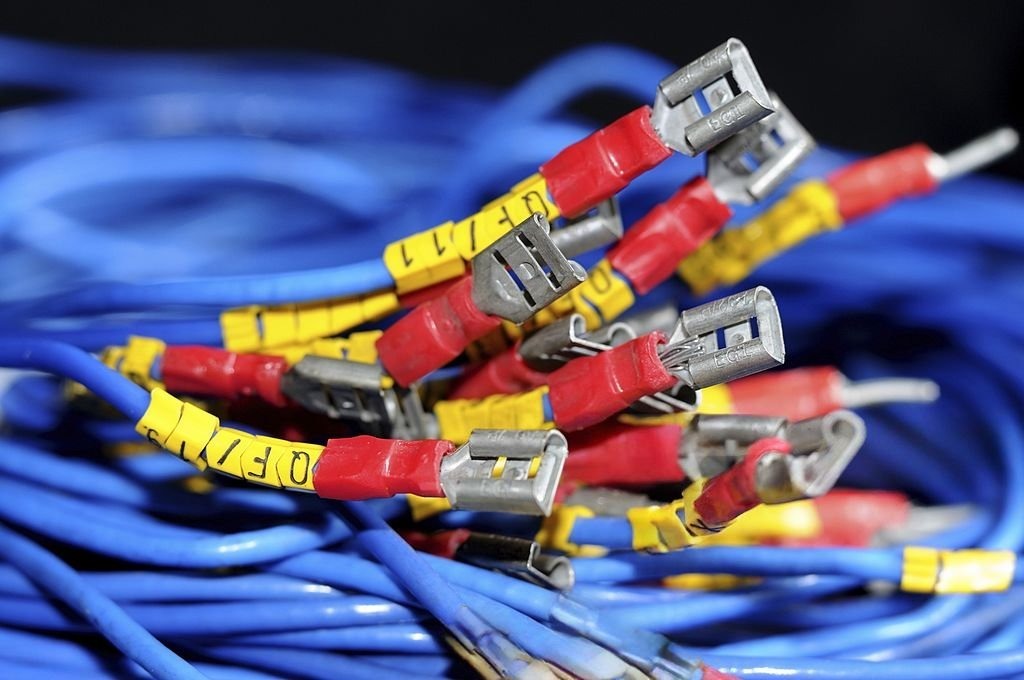

Cable harnesses—also known as wiring harnesses or cable assemblies—are the nervous system of modern technology. They manage power distribution, ensure signal integrity, and provide mechanical stability. These harnesses are found everywhere, from passenger vehicles and aircraft to life-saving medical devices and heavy-duty industrial machinery. Their performance directly affects reliability and safety.

Standards are the backbone of cable harness production. Created by industry organizations, government agencies, and OEM alliances, these standards specify how harnesses must be designed, manufactured, and tested. They remove ambiguity, increase trust between suppliers and buyers, and ensure global compliance.

This article reviews why cable harness standards matter, key frameworks across industries, testing methodologies, buyer checklists, applications, and future developments.

Importance of Cable Harness Standards

Benefits of Compliance

Safety: Prevent overheating, arcing, and fire hazards.

Reliability: Ensure stable performance in vibration, dust, moisture, and thermal cycling.

Interoperability: Enable compatibility across components from different suppliers.

Global Market Access: Meet regulatory requirements (UL/CSA in North America, CE in Europe, CCC in China).

Supplier Evaluation: Provide objective criteria to qualify vendors.

Risk Management: Minimize liability from failures, recalls, or warranty claims.

Customer Confidence: Demonstrate adherence to international quality standards.

Traceability: Require consistent labeling and identification for production tracking.

Core Cable Harness Standards

Overview of Major Standards

Testing and Validation Requirements

Key Test Categories

Industry-Specific Applications

Buyer’s Compliance Checklist

Request IPC/WHMA-A-620 certification.

Verify UL/CSA file number.

Confirm IATF 16949 certification (automotive).

Check ISO 13485 compliance (medical).

Review test reports: Hipot, Tensile, Vibration, Salt Spray.

Ensure traceability of components and First Article Inspection (FAI).

Evaluate adherence to Design for Manufacturability (DFM).

Audit compliance with Statistical Process Control (SPC).

Review RoHS and REACH certifications.

Request IP66/IP67 sealing compliance.

Future Directions

EV Harness Standards: ISO 19642 expansion for high-voltage systems.

Automation: Robotic crimping and inline SPC monitoring.

Supply Chain Management: Global audit requirements and traceability systems.

Sustainability: Stricter RoHS, REACH, and WEEE compliance.

Prototyping: Digital modeling and First Article Inspections.

Cybersecurity: EMI protection and encryption for smart harnesses.

Final Thoughts

Cable harness standards form the foundation of quality and reliability across industries. Compliance with frameworks such as IPC/WHMA-A-620, IATF 16949, AS9100, ISO 13485, and UL/CSA ensures that every assembly meets strict technical, safety, and regulatory requirements. By aligning with these benchmarks, manufacturers deliver harnesses that are consistent, durable, and trusted worldwide.

Organizations that maintain these standards not only reduce risks and avoid costly failures but also demonstrate a commitment to excellence that strengthens customer confidence and supports long-term growth.

Partner with Celestix

Looking for wiring harnesses engineered to global standards? Partner with Celestix Industries for cable harnesses compliant with IPC/WHMA-A-620, ISO 9001 frameworks, IATF 16949 automotive certifications, and UL/CSA listings. Contact us today to discuss your wiring harness testing standards, electrical harness reliability goals, and future-proof design needs.