The Role of Wire Harnesses in AI-Powered Appliances

1. Introduction: The Hidden Backbone of Smart Technology

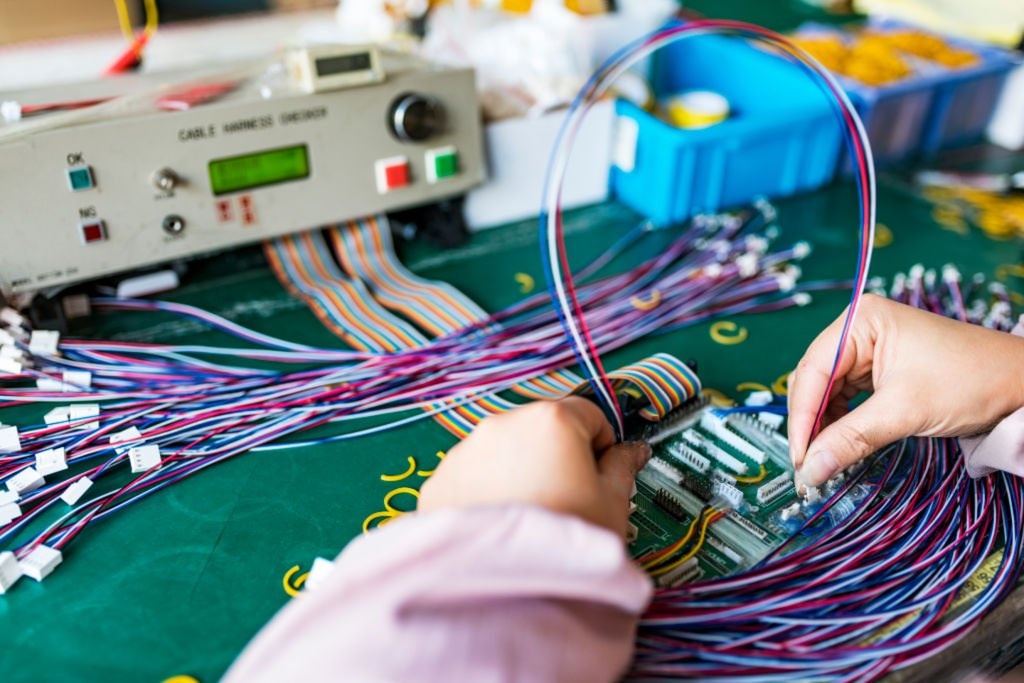

Artificial intelligence (AI) has transformed home and industrial appliances, evolving them from mechanical systems into intelligent, connected devices. From refrigerators tracking inventory to ovens adjusting temperatures automatically, AI powers these features—but it’s the wire harness that enables them to function.

Wire harnesses act as the electrical and data nervous system of every AI appliance. They transmit power, carry signals, and connect control boards, sensors, and power units. Without them, intelligent appliances cannot perform reliably or safely.

2. The Growing Complexity of Smart Wiring Systems

AI-powered appliances now combine AC power, DC control, and high-speed digital communication. This hybrid design requires more innovative wiring systems that can balance power flow with data transfer integrity.

Modern harnesses must handle multi-signal routing, shield against interference, and remain flexible enough to fit into compact enclosures.

3. Core Components of AI Harnesses

AI harness systems include several functional subsystems:

High-Power Harnesses – Powering motors, compressors, and inductive loads.

Low-Voltage Harnesses – Supplying microcontrollers and logic boards.

Data Harnesses – Handling CAN, I²C, or serial communication.

Diagnostic Harnesses – Monitoring current, voltage, and heat for feedback.

Safety Harnesses – Managing Surge and Overload Protection.

4. Design Innovations Driving Harness Evolution

Modern AI harnesses reflect key innovations that enhance performance and service life:

Hybrid Power-Data Lines – Carry both power and data, reducing complexity.

Flexible Flat Cables (FFC) – Allow compact routing in small appliances.

Twisted-Pair Shielding – Reduce EMI for improved signal reliability.

Micro-Terminals – Miniaturization Saves Space and Improves Accuracy.

Embedded Diagnostic Leads – Allow real-time harness monitoring.

5. Manufacturing and Quality Assurance

Producing AI harnesses requires automation, precision, and compliance with global standards.

Manufacturing Workflow

Wire cutting and stripping with CNC control.

Crimping monitored by Crimp Force Monitors (CFM).

Automated layout using robotic harness boards.

Optical inspection and X-ray validation.

HiPot and continuity testing for insulation and connection integrity.

RFID labeling for digital traceability.

6. Predictive Diagnostics and Real-Time Monitoring

Harnesses in AI appliances now integrate sensors that collect data on load, temperature, and current. These are used by AI algorithms to predict issues before they cause failure.

Predictive harnesses cut maintenance downtime by 35–40%, providing OEMs with measurable ROI through reduced service calls.

7. Sustainability and Global Compliance

Celestix harnesses follow eco-friendly practices that meet global standards.

Sustainability Highlights

Recycled conductors and bio-based insulation.

Halogen-free materials with improved heat resistance.

Solar-powered manufacturing lines.

Compliance with RoHS, REACH, WEEE, and ISO 14001.

8. ROI and Performance Comparison Table

9. The Future: Intelligent Harness Ecosystems

Future harnesses will become cyber-physical systems that communicate, adapt, and self-optimize.

Embedded microcontrollers for fault detection.

Digital twin mapping for real-time virtual testing.

Cloud-linked harness analytics for continuous improvement.

Edge computing for local AI decision-making.

OTA firmware updates for adaptive hardware optimization.

By 2030, intelligent harness networks will power most smart appliances, linking them directly to smart grids and energy-efficient homes.

10. Conclusion and Call to Action

AI provides intelligence; wire harnesses deliver reliability. As appliances evolve, so must their wiring systems—stronger, safer, and smarter.

Partner with Celestix Industries for harness systems designed for AI-driven environments. Our assemblies meet global standards, offer predictive capability, and provide measurable ROI.

Contact Us

Website: www.celestixindustries.com

Email: sales@celestixindustries.com

Celestix Industries — Wiring the Future of Intelligent Appliances.