Accelerate Assembly with Pre-Tested, Quality-Assured Harnesses

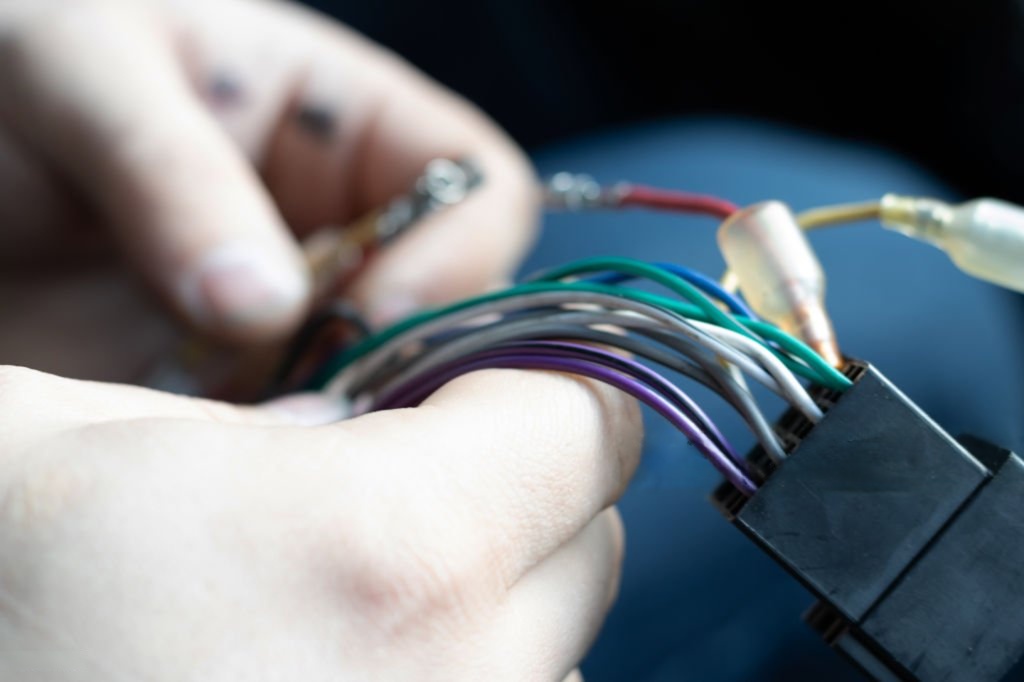

In high-mix, high-stakes industries—automotive, aerospace, medical, and industrial automation—the wiring harness is more than a bundle of wires. It's the backbone of system integrity, reliability, and efficiency. Yet, one of the most underestimated ways to accelerate final product assembly is to start with pre-tested, quality-assured wire harnesses.

At Celestix Industries India Pvt. Ltd., we manufacture harnesses that are not only custom-built to spec—but also exhaustively tested before they reach your floor. Here's why that makes all the difference.

From pre-tested wiring harnesses that reduce lead times to high-reliability wiring harness solutions for harsh environments, our approach is engineered for performance, scalability, and peace of mind.

1. Speed Starts with Certainty

Every untested harness on your assembly line is a variable—a potential defect, delay, or disaster. Pre-tested harnesses remove that uncertainty.

Celestix guarantees 100% testing:

These automated wiring harness testing practices enable plug-and-play installation on the customer’s production line—no troubleshooting, no line halts.

Benefits:

Minimized incoming inspection time

Consistent quality across every lot

Improved production flow and predictability

Increased operator confidence during assembly

Reduced reliance on post-assembly diagnostics

2. Reduce Integration Risk with Standardized Quality

Celestix harnesses comply with top-tier certifications:

IATF 16949 (automotive quality standard)

AS9100 (aerospace quality)

ISO 9001, 14001, 45001

CE, UL, RoHS, REACH

IPC/WHMA-A-620, J-STD-001

Why this matters:

Ensures compliance with global OEM requirements

Reduces re-validation burden on customers

Validates material durability, traceability, and workmanship

Enables risk-free integration across platforms

We apply durable wiring harness materials like flame-retardant sheathing, high-temp insulation (PTFE, silicone), and plated copper for signal integrity. Electrical harness testing standards are enforced on every unit, regardless of volume or complexity.

3. Faster Takt Time, Lower Downtime

Faulty harnesses slow down production. Our clients report:

92% reduction in harness-related faults

30–50% faster assembly line throughput

No post-installation debugging needed

Fewer line stops during peak hours

Common delays avoided with Celestix harnesses:

Our harnesses support continuous production across single-shift or 24/7 operations—enabling manufacturers to optimize OEE (Overall Equipment Effectiveness).

4. Modular, Pre-Tested Subassemblies Enable Leaner Workflows

We specialize in custom wiring harness solutions designed for:

Just-In-Time manufacturing

Vendor-Managed Inventory (VMI)

Line-side assembly kits

Kanban stocking models

Types of Modular Harnesses We Provide:

Multi-connector automotive harnesses

Over-molded power plugs

PLC signal harnesses

Infotainment and sensor routing bundles

Safety system harnesses for ADAS

Advantages:

Shorter changeover times

Simplified training for line operators

Seamless integration with ERP and logistics systems

Optimized packaging for international shipping

Clear labeling to reduce picking and routing errors

5. Designed for Assembly, Engineered for Uptime

Our harnesses are built with DFM/DFMA principles:

Color-coded wires and keyed connectors for foolproof mating

Strain relief boots to withstand vibration

Labeling, barcoding, and serialization for traceability

Design Features That Support Long Life:

Over-molding for ingress protection

Routing optimization for minimal stress

Compliant with IPC/WHMA-A-620 Class 3 reliability

Crimp geometry validated through cross-section analysis

Used In:

Wiring harness for medical devices

Aerospace wiring harness quality-critical zones

EV battery and drivetrain modules

Industrial automation and control panels

These design standards reduce field failures and help customers avoid costly recalls, rework, and warranty claims.

6. When Time Is Critical, Reliability Is Non-Negotiable

Every Celestix harness comes with:

12-month performance warranty

Certificate of Conformance (COC)

In-house test reports

FA/PPAP documentation for automotive clients

Capability to support engineering change notices (ECNs)

Manufacturing Capabilities:

We maintain stock of critical components, enabling faster turnaround and a buffer against global supply disruptions. With lean and agile production systems, we adapt quickly to urgent customer demands.

Conclusion: Speed Without Sacrifice

In 2025, engineering buyers prioritize performance, reliability, and fast turnaround. Celestix delivers on all three:

Certified, pre-tested harness reliability

Wiring harness complexity solutions

Optimized for total cost of ownership

Backed by engineering support and global logistics

Compliant with industry-specific quality and safety standards

We do not just ship parts—we deliver consistency, trust, and engineering excellence across every batch.

Ready to Eliminate Delays and Defects?

Connect with Celestix Industries today to:

Request a Quote: https://www.celestixindustries.com/GetaQuote

Submit Your Specs: https://www.celestixindustries.com/contact-us

Email Us Directly: info@celestixindustries.com

Pre-Tested.

Quality-Assured.

Built for Your Assembly Line.

Celestix can accelerate your build cycles—without compromising on quality.