Are You Still Testing Harnesses Manually? Here’s What You’re Missing

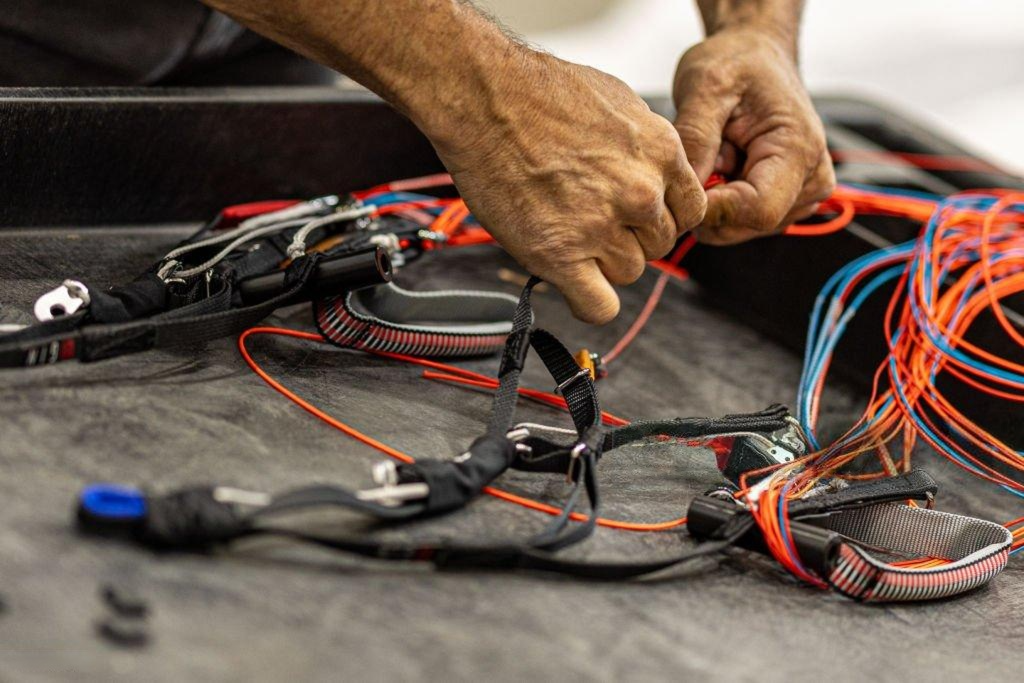

In manufacturing, every connection matters. Especially when you're building automotive EV systems, medical devices, aerospace avionics, or industrial automation controls—systems where wiring harnesses are not just passive components, but critical infrastructure.

Yet, in 2025, many manufacturers still rely on outdated manual wiring harness testing techniques—using multimeters, buzzers, or basic visual checks. While this may suffice for hobby kits or basic consumer products, in high-stakes industries, manual testing is not just outdated—it’s a liability.

At Celestix Industries, we’ve seen firsthand how this gap in testing leads to reliability issues, poor compliance, and lost efficiency. This blog is a reality check: if you're still testing wiring harnesses manually, here's exactly what you're missing—and how wiring harness testing automation redefines quality, speed, and traceability.

1. Manual Testing in Context: How Did We Get Here?

Manual testing evolved in an era when harnesses were simpler, systems were analog, and design margins were broader. But today's environment is very different:

Wiring harness complexity has increased by over 200% in the last decade.

Safety-critical applications now dominate demand—from ADAS in vehicles to life-saving equipment in hospitals.

Global compliance mandates such as AS9100, ISO 16750-4, and IPC/WHMA-A-620 testing standards are stricter and more data-driven than ever before.

In this new paradigm, manual wiring harness testing issues include subjectivity, inefficiency, and a lack of documentation. Even if your operators are experienced, even if your failure rates seem acceptable, manual testing creates a blind spot you can no longer afford.

Furthermore, industries like aerospace and automotive are demanding more from suppliers. Wiring harnesses must withstand extreme conditions—high vibration, temperature fluctuations, salt spray, moisture, and electromagnetic interference. These demands necessitate automated systems capable of executing repeatable, high-voltage, multi-point tests.

2. The Illusion of “Good Enough”: Why Manual Testing Fails Modern Demands

Manual methods rely on human eyes, hands, and memory—all of which are variable, limited, and prone to error.

2.1 Common Manual Testing Shortcomings:

Missed Connections

Subjectivity in Visual Checks

Inconsistent Electrical Testing

No Data Trail

Lack of Scalability

Incompatibility with Compliance Standards

Additionally, manual testing cannot consistently perform high-voltage stress tests or insulation resistance validation, which are essential for today’s high-current and high-voltage harnesses used in EV battery systems and aerospace power distribution.

3. The Engineer’s Perspective: What True Testing Should Look Like

Environmental Harness Testing Explained

True wiring harness quality control requires more than continuity checks. It must include:

Electrical continuity testing harness

Insulation resistance testing harness

Hipot testing wiring harness

Vibration testing the wiring harness

Thermal cycling harness testing

Environmental testing wiring harness (includes IP67, salt spray exposure, and fatigue resistance)

Pull testing and crimp quality testing harness analysis

Wiring harness failure mode prediction through accelerated life tests

Manual vs. Automated Testing

4. The Real Cost of Manual Testing: Engineering Risk + Business Loss

Manual testing exposes your operations to critical risks:

Unverified crimps → wiring harness failure modes

No records → compliance and liability issues

Slower cycle time → lost revenue

Missed defects → rework, warranty claims, or recall

There’s also the hidden cost of re-engineering and testing returned units, loss of customer confidence, and delays in production timelines when a test plan fails. These costs significantly outweigh the investment required for automated testing systems.

Companies still relying on manual methods cannot effectively implement wiring harness quality assurance, SPC, or traceability demanded by OEMs.

5. Automation at Celestix: Built-In, Not Bolted On

Our end-to-end automated wiring harness testing integrates:

CableEye automated testing (continuity + fault map)

Hipot, IR, and shield continuity

Pull test wiring harness checks

Environmental validation per ISO 16750-4, HALT, and HASS

Digital harness testing traceability linked to QA systems

We go beyond basic test coverage to include:

Custom fixture design to match your harness geometry

Auto-generated inspection reports with pass/fail thresholds

Batch-level SPC analysis for process improvements

Integration with MES/ERP systems for real-time data feedback

This results in:

Harness testing efficiency (test cycles <3 min)

Wiring harness testing time reduction (up to 70%)

Automated harness testing ROI via labor and scrap reduction

Peace of mind through high-reliability wiring harness testing

6. Custom Testing Solutions for Every Industry

We provide custom harness testing solutions across sectors:

Automotive harness testing solutions for EV and ICE platforms

Aerospace harness testing equipment for flight-certified wiring

Medical device harness testing for critical diagnostic and therapeutic use

Industrial wiring harness testing for control panels and automation systems

We support Siemens NX and EPLAN integrations to import netlists directly into our automated test equipment harness systems.

We also offer:

Quick-turn prototyping validation for new harness designs

Rework loop diagnostics for field returns

Mixed-signal and RF harness testing capabilities

7. 2025+ Outlook: The Business Case for Automation

7.1 Challenges in Manual Testing

Inability to scale

Inconsistent quality

Lack of process visibility

Difficulty proving compliance during audits

Delays in production ramp-up or PPAP approval

7.2 Benefits of Automated Harness Testing

Consistent, error-free testing across batches

Scalability to support 5x–6x production volume

OEM-preferred testing documentation

Data-driven insights for defect detection and quality improvement

Faster time-to-market through real-time process feedback

OEMs now require digital test reports as part of supplier qualification. Automation isn’t optional—it’s essential.

8. Celestix Advantage in Harness Testing Automation

What makes Celestix stand out in automation in harness manufacturing:

Certified under IPC/WHMA-A-620, IATF 16949, ISO 9001, ISO 14001, and ISO 45001

In-house advanced harness testing technology

Real-time wiring harness defect detection

Fast onboarding of new projects

Lab validation per industry standards (IP67, Salt Spray, Vibration, Thermal)

A dedicated engineering team to help define your testing specification

Support for automated test equipment harness configurations for global rollouts

9. Frequently Asked Questions (FAQs)

Q1: Is automated harness testing worth it for low-volume production?

Yes. Even in low-volume or prototype builds, automation ensures that quality issues are detected early—when they’re cheaper to fix.

Q2: Can Celestix integrate automated testing into our legacy systems?

Absolutely. We support integration with existing MES, ERP, and quality control systems.

Q3: How long does it take to transition from manual to automated testing?

Most implementations are complete in 2–4 weeks, including fixture development.

Q4: What certifications do your systems meet?

IPC/WHMA-A-620, ISO 16750-4, AS9100, ISO 9001, and other global compliance standards.

Q5: Do you offer post-deployment support?

Yes. Training, test program updates, remote support, and technical consulting are all part of our offering.

10. Looking Ahead: The Future of Harness Testing

The next decade will reshape harness testing through smart automation:

AI-assisted diagnostics that identify failure trends

Predictive analytics tied to manufacturing KPIs

Machine vision inspection for connector and label validation

Cloud-based test data for global traceability

Digital twin integration for fault simulation

Celestix is already preparing for this shift—ensuring our partners remain future-proof.

11. Make the Shift. Build Reliability Into Every Connection.

If you're still relying on manual testing, you're putting your operations at a competitive disadvantage. Now is the time to adopt a more intelligent, scalable, and data-driven approach to wiring harness validation.

Reach out to our engineering specialists to discuss:

Your current testing challenges

Customized automation opportunities

Integration with your existing systems

Contact our team today:

Email: info@celestixindustries.com

Quote Request: Request a Custom Testing Quote

Celestix delivers future-ready, high-precision, and compliance-driven automated harness testing solutions trusted by global OEMs and Tier-1 suppliers.