Automotive Wiring Harnesses: Adapting to Software-Defined Vehicles (SDVs)

Introduction: The Wiring Backbone of Intelligent Mobility

Today’s automotive engineering is undergoing a historic transformation. What was once a mechanical system controlled by discrete electronic components is now evolving into a connected, software-updated, and data-centric environment. This paradigm shift has given rise to a new class of vehicles: Software-Defined Vehicles (SDVs)—a term that now dominates innovation roadmaps in the automotive electronics sector.

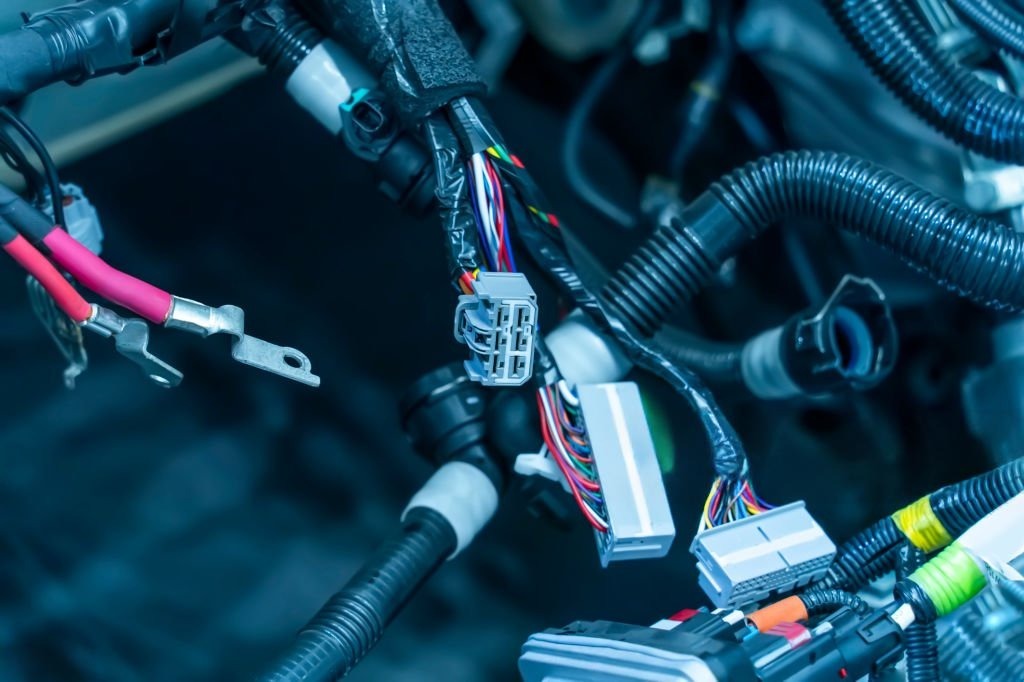

Unlike traditional automobiles, SDVs rely heavily on central computing, real-time data processing, over-the-air (OTA) software updates, and integrated communication across every subsystem. In this context, the humble automotive wiring harness has taken on a critical new role. No longer just a passive electrical conduit, it has become an active enabler of automotive connectivity, intelligence, and safety.

At Celestix Industries India Pvt. Ltd., we are redefining what a harness can do. As a vertically integrated custom wiring harness supplier, we’ve engineered our product lines to meet the rigorous demands of software-defined vehicle architecture, electric vehicle wiring, and advanced vehicle electrical architecture through deep technical innovation, precision wiring harness manufacturing, and customer-centric agility.

This article explores the evolving role of automotive wiring harnesses for software-defined vehicles, offering insights into:

How wiring harness design principles are changing in the SDV era

The latest innovations in EV wiring harness technology

Why high-voltage wiring harnesses for EVs must meet new performance standards

How Celestix delivers automotive wiring harness solutions for ADAS, autonomy, and connected mobility

What makes us a trusted SDV electrical system supplier to OEMs and Tier-1s worldwide

We also address:

Wiring harness challenges in software-defined vehicles

How to evaluate wiring harness reliability in SDVs

Which automotive wiring harness standards govern SDV manufacturing

The impact of materials, testing, and quality control on SDV safety and scalability

Why future-ready harnessing includes digital twin wiring harness design, optical wiring harness automotive technology, and full IPC/WHMA-A-620 and IATF 16949 compliance

If you're planning to buy automotive wiring harnesses for next-generation platforms or need guidance on customizing wiring harnesses for autonomous vehicles, this guide is engineered for you.

Request a Quote Today

Looking for a reliable EV wiring harness manufacturer or a custom wiring harness supplier for your SDV platform?

Prefer to discuss your project? Email us at: info@celestixindustries.com

1. Vehicle Architecture: Mechanical to Software-Defined

Harness Role in SDVs

Power and Data Convergence – Enables simultaneous routing of electrical power and communication signals.

Future-Proof Modularity – Facilitates flexible upgrades, ECU remapping, and hardware retrofit.

System Redundancy – Built-in fault tolerance, alternative paths, and diagnostic interfaces.

Compliance and Certification – Conforms to ISO 26262 and cybersecurity frameworks.

Signal Integrity Assurance – Supports high-bandwidth, low-latency protocols with EMI shielding.

Extended Service Life – Harnesses validated for >15 years to match SDV software lifecycle.

Edge Data Readiness – Designed to support AI/ML workloads in autonomous systems.

Zonal Harness Architecture

Zonal Electrical Architecture Overview:

[Central Compute Unit]

|

-------------------

| | |

[Zone A][Zone B][Zone C]

| | |

Sensors Actuators Displays

Zonal Benefits Breakdown

Celestix Zonal Harness Innovations

Modular kits engineered for specific vehicle zones

Diagnostic-ready connectors with built-in test points

RFID cable tagging for real-time tracking and service logging

Hybrid power/data routing compliant with ISO 19642/6722

Sealed connectors to IP67/IP69K with anti-vibration fittings

Integrated smart ICs for real-time temperature and strain monitoring

AS9100 and automotive-grade compliance for safety-critical applications