Built to Fit, Built to Last — Wire Harnesses for Every Industry

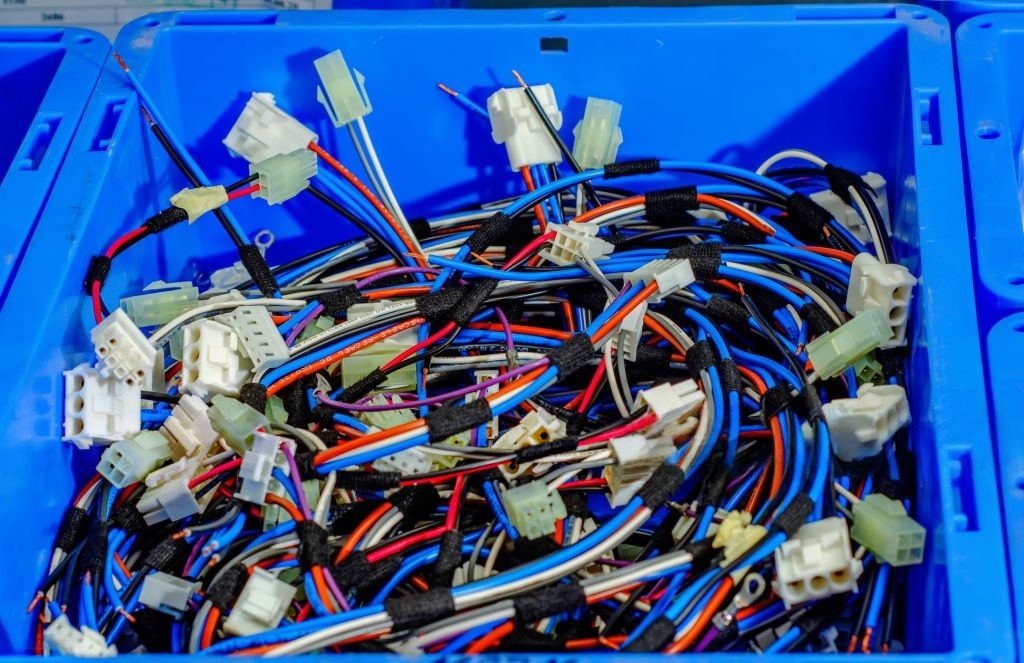

In today’s electrically driven world, wiring harnesses are not just a cluster of wires — they are the engineered nervous system of modern technology. They carry power, transmit signals, and safeguard critical functions across industries where reliability is essential.

From automotive harnesses in electric vehicles to aerospace wiring that must endure extreme environments, and from industrial applications to medical devices demanding absolute precision, wiring harnesses form the backbone of global innovation. At Celestix Industries, we build harnesses that are built to fit and built to last.

Built to Fit: Precision Engineering for Every Industry

No two applications are the same. The needs of an EV battery harness differ greatly from those of a telecom fiber optic assembly or a surgical device cable. That’s why we specialize in custom harnesses engineered to match exact specifications and industry requirements.

We apply Design for Manufacturability (DFM) and Design for Assembly (DFA) principles, supported by advanced CAD tools and digital twins. This allows us to:

Optimize layouts

Simulate real-world conditions

Streamline assembly processes

All of this ensures reliability from the design stage onward.

Material Selection: The Foundation of Performance

Every harness begins with careful material selection to balance performance, safety, and cost:

Copper conductors — maximum conductivity and durability

Aluminum wiring — lightweight for aerospace and EV designs

Insulation materials — PTFE insulation (high temperature and chemical resistance), silicone insulation (flexibility in extremes), low smoke zero halogen (LSZH) (safety in enclosed environments)

Connectors and terminal plating — tin (affordable), nickel (heat-resistant), silver (conductive), gold (aerospace durability)

Protective sheathing — braided sleeving, corrugated tubing, heat shrink, and over-molded jackets

This engineering-first approach ensures every harness is built to fit its environment — whether inside a car dashboard, a robotic arm, or a jet engine.

Error-Proofing and Routing Design

Our engineers apply:

Standardization

Error-proofing (poka-yoke)

Optimized routing design

We also add strain relief systems, grommets, and molded boots at high-stress points to prevent fatigue. Routing pathways are designed to minimize EMI, avoid excessive bending, and improve maintainability.

Built to Last: Reliability Under All Conditions

When harnesses fail, consequences can be severe. That’s why quality control is at the core of our process. Every harness undergoes 100% inspection, which includes:

Continuity testing — ensures no open or short circuits

Insulation resistance testing — verifies performance under high voltages

Hipot testing — confirms insulation strength

Environmental testing — thermal cycling, vibration, salt spray, humidity exposure

We also validate products against IP ratings up to IP69K, ensuring protection from dust, water jets, and immersion.

Certifications That Guarantee Trust

We meet and exceed international standards:

IPC/WHMA-A-620 — Wiring Harness Manufacturing Standard

AS9100 — Aerospace Quality Management

ISO 9001, IATF 16949, ISO 14001 — Quality and environmental compliance

RoHS, REACH, UL, CE, BIS — Safety and sustainability certifications

Combined with total quality management and Six Sigma practices, these certifications ensure zero-defect outcomes and long-term trust.

Cross-Industry Applications: One Partner, Many Solutions

Celestix harnesses serve diverse industries:

Automotive harnesses — engines, chassis, infotainment, EV systems

Aerospace wiring — lightweight, shielded, high-temperature solutions

Industrial applications — modular, rugged harnesses for robotics and heavy machinery

Medical devices — shielded, biocompatible, precision wiring

Telecom and consumer electronics — compact, EMI-protected harnesses

We integrate rapid prototyping, automation, and scalable production. Our mix of manual expertise and robotic precision supports both low-volume prototypes and mass production

Supplier Collaboration and Buyer Confidence

In B2B procurement, buyers evaluate more than cost. Decisions are shaped by buyer psychology, risk aversion, and the importance of trust building. Key factors include:

Total cost of ownership

Technical expertise

Supplier reputation

We address these by offering:

Collaboration from design to delivery

Failure mitigation strategies (redundant testing, continuous monitoring)

Supply chain resilience (critical stock, vendor-managed inventory)

Transparency through certifications, traceability, and documentation

This positions Celestix as a partner, not just a supplier.

Why Celestix?

We are engineers first, manufacturers second. Our engineering depth, advanced processes, and customer-first DRIVE culture make us the trusted partner in industries where failure is not an option.

100% inspection and testing for every harness

Scalable capacity with advanced automation

Proven expertise in failure mitigation

A reputation built on trust and reliability

Flexible support for customization and rapid scale-up

Get a Harness That Performs

Looking for a wiring harness supplier who understands your technical requirements and the challenges of supply chain management? Partner with Celestix for custom harnesses designed with foresight, tested with rigor, and manufactured for endurance.

Built to fit. Built to last. That’s Celestix.

Reach out today:

Email: info@celestixindustries.com

Quote form: Get a Quote

Contact form: Contact Us