Cutting Costs Without Cutting Corners: Smarter Wiring Harness Solutions

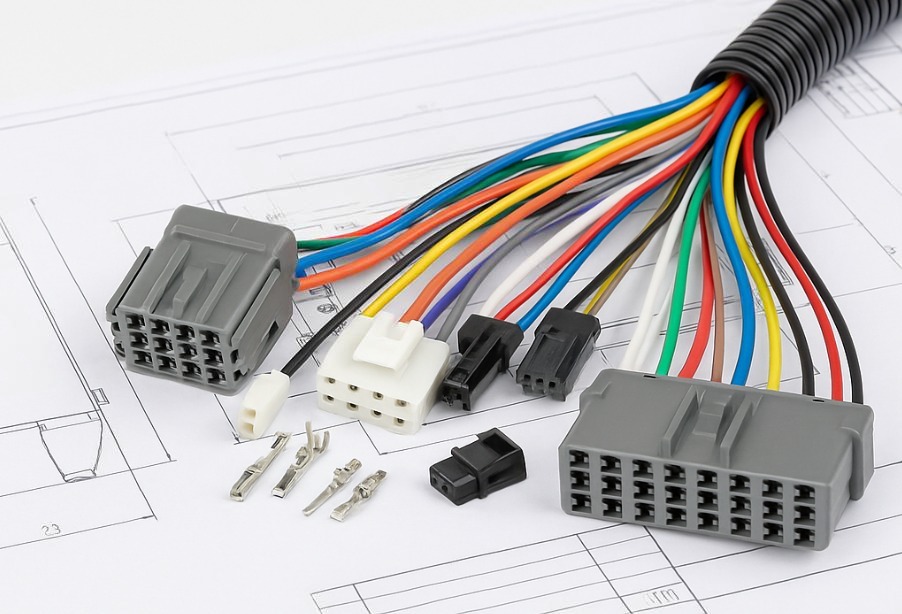

In a high-stakes manufacturing environment, wiring harness cost reduction is critical—but compromising on quality is never an option. At Celestix Industries, we specialize in providing smart wiring harness solutions that are cost-effective, compliant, and customized to meet your exact specifications—without cutting corners.

Wiring harnesses are often underappreciated in cost optimization discussions, yet they are among the most vital components in any electrical or electronic system. From automotive OEMs and EV innovators to medical device manufacturers and industrial automation leaders, efficient wiring harness design delivers long-term cost savings, improved reliability, and reduced assembly time—while avoiding expensive failures.

Effective cost optimization in harness manufacturing is not achieved through shortcuts; it requires a strategic blend of intelligent design, production efficiency, material insight, and forward-thinking engineering. While price remains a factor, true value lies in engineering precision, defect prevention, and flexible scalability across production runs.

Here’s how manufacturers in sectors such as automotive, aerospace, consumer electronics, medical, and telecom can achieve affordable wiring harness production without compromising performance, safety, or scalability.

1. Cost-Effective Wiring Harness Design

Key Strategies:

Standardizing connectors and terminals reduces sourcing complexity and enhances interchangeability.

Modular wiring harness design simplifies installation and supports scalable production.

Design for Manufacturability (DFM) ensures designs are optimized for efficient, repeatable production.

Simplifying harness layouts eliminates excess splicing and minimizes cable length.

Virtual prototyping and CAD tools identify design flaws early and reduce rework costs.

Thermal and EMI simulations enable predictive performance analysis.

Design reuse libraries reduce engineering cycles and prevent common design errors.

Wire bundling optimization minimizes routing complexity and material usage.

Cross-functional design reviews uncover cost-saving opportunities across product families.

2. Smarter Material Selection = Long-Term Savings

Recommended Materials:

Aluminum – Lightweight, conductive, ideal for EVs and aerospace.

PVC/XLPE – Budget-friendly and reliable for general industrial use.

Tinned Copper – Corrosion-resistant and durable.

Hybrid Composites – Superior strength-to-weight ratio.

TPE – Excellent flexibility for dynamic applications.

Halogen-Free Insulation – Ensures fire safety compliance.

Glass-Filled Nylon – Best for structural components and high temperatures.

LSZH Jackets – Suitable for confined or regulated environments.

Cost Comparison Table:

Strategic material selection enables performance optimization through tailored electrical, thermal, and mechanical characteristics—without incurring unnecessary cost overhead.

3. Lean and Automated Wiring Harness Manufacturing

Lean Manufacturing Benefits:

Reduced waste and process variability

Lower lead times

Consistent work quality

Higher first-pass yield rates

Automation Technologies in Use:

Wire cutting, stripping, and crimping automation

Laser wire identification

Ultrasonic splicing

Fixture-assisted assembly stations

Barcode-driven traceability systems

Automated wire twisting for EMI protection

In-line electrical testing for process validation

4. In-House Capabilities Drive Cost Control

Celestix’s Integrated Capabilities:

Wire extrusion and conductor processing

Overmolding of connectors and strain reliefs

PCB integration for hybrid assemblies

Functional and load testing

Vibration, thermal, and ingress testing in-house

Custom mold design and maintenance

Operational Benefits:

Eliminates third-party markup

Accelerates prototyping and change response

Improves coordination between design and production teams

5. Quality Control That Delivers ROI

Robust QC Framework:

IPC/WHMA-A-620 Class 3 compliance inspections

Environmental stress screening (ESS)

Dielectric strength and pull testing

Microscopic terminal inspections

Cross-sectional analysis of crimps

Inline testing for high-volume production lines

Automated Optical Inspection (AOI) for alignment verification

6. Supplier Collaboration and Strategic Sourcing

Collaborative Procurement Approach:

Engage suppliers during early-stage development

Optimize the bill of materials with cost-efficient components

Build redundancy into sourcing plans

Negotiate volume-based pricing structures

Integrate logistics for just-in-time (JIT) delivery

Procurement Benefits:

7. Focus on Total Cost of Ownership (TCO)

Key TCO Influencers:

Assembly and installation time

Field failure rates and warranty costs

Service training and support complexity

Diagnostic ease and system uptime

Certification and regulatory maintenance

Final Thoughts: Value Engineering You Can Count On

Celestix Delivers:

Durable, cost-effective, and standards-compliant wiring harnesses

Scalable production and responsive change management

Engineering collaboration that ensures performance without overdesign

Whether your focus is automotive cost reduction, aerospace efficiency, or lean industrial harnessing, Celestix is your trusted partner for smarter, future-ready wiring harness solutions.

Contact Celestix:

Email: info@celestixindustries.com

Request a Quote: Get a Quote

Let’s simplify, optimize, and grow—without compromise.