Design Gaps in Wiring Harnesses: Root Causes, Engineering Solutions, and How Celestix Builds Reliability In

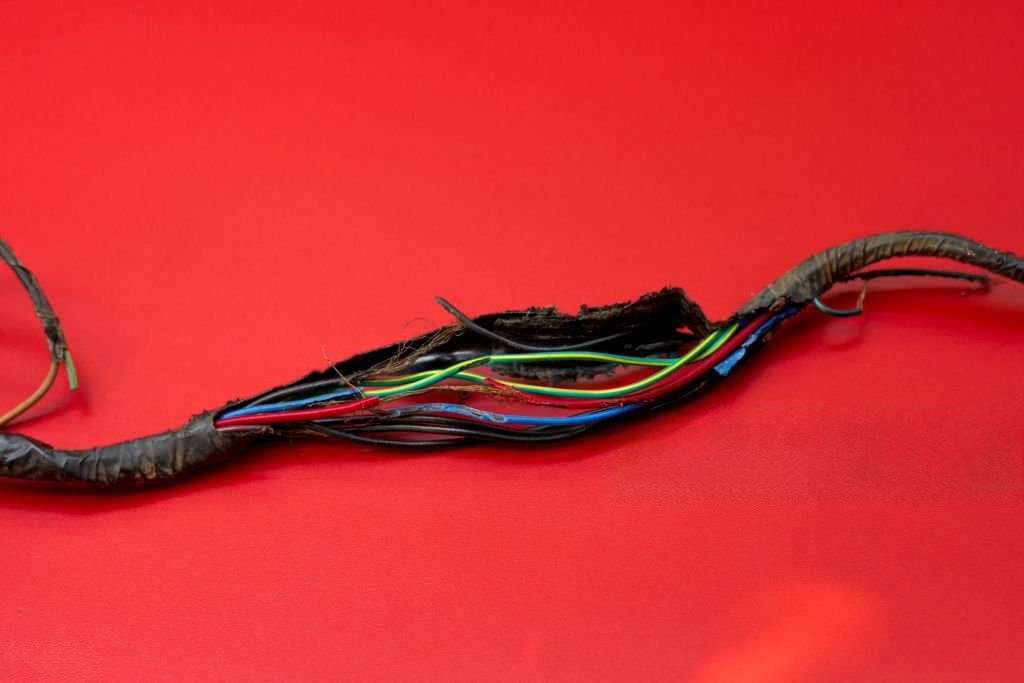

Wire harnesses are the backbone of modern electronic systems—yet even a minor oversight in design can lead to catastrophic failure. From short circuits and voltage drops to corroded connectors and broken conductors, every fault tells the story of a preventable design flaw. In high-stakes industries like automotive, aerospace, and industrial automation, these failures translate to lost revenue, safety risks, and product recalls.

At Celestix Industries, we engineer reliability into every harness we build. This blog uncovers the most common design gaps that lead to wiring harness failures—and the proven methods our engineers use to prevent them.

8 Critical Causes of Harness Failures—And How to Engineer Them Out

What High-Reliability Harness Engineering Really Looks Like

1. Certified Quality. Built Into Every Stage

Celestix Industries operates under globally recognized quality frameworks:

IPC WHMA A-620 Class 3 (aerospace/defense grade)

IATF 16949 (automotive)

AS9100, ISO 9001, ISO 14001

RoHS and REACH compliance for environmental safety

Each harness undergoes inspection for:

Vibration durability

EMI resistance

Insulation integrity

Mechanical strength

2. Testing That Simulates Real-World Extremes

Continuity, impedance, and contact resistance checks

Hipot and insulation resistance testing (ISO, IEC standards)

Thermal cycling, humidity, and salt spray

Tensile and flex fatigue testing

HALT to expose early-life vulnerabilities

3. Material Selection With Precision

PTFE, FEP, and XLPE for thermal/chemical resilience

Class K stranding for high-flex assemblies

LSZH jackets for confined or safety-sensitive installs

Nickel, silver, or gold plating for harsh environments

4. Smart Manufacturing, Not Just Assembly

Virtual prototyping (Siemens NX, RapidHarness)

Error-proofed designs with keyed connectors and color-coded wiring

Serialized traceability to the component level

Visual work instructions and in-line QA checkpoints

5. Root Cause Prevention, Not Just Detection

Celestix’s CAPA systems don’t wait for failure—they prevent it:

SPC data monitoring per lot

Root cause reports with photographic evidence

Supplier collaboration to eliminate recurring design flaws

Why Celestix Wiring Harnesses Outlast the Competition

When a product fails in the field, it’s not just a wiring issue—it’s a trust issue. Celestix engineers every harness to meet the harshest operational demands across EVs, aerospace, medical, and industrial systems.

Our designs eliminate known failure triggers before they leave the design bench. We simulate stress. We over-test. We validate. And we stand behind every unit we deliver.

Ready to Eliminate Design Gaps in Your Harnesses?

Don’t let hidden design flaws compromise your product. Whether you're developing EV systems, aerospace controls, or rugged industrial equipment, Celestix delivers wire harness solutions engineered for precision and durability.

Get Started:

Request a Design Gap Audit

Speak with a Harness Engineering Specialist

Receive a Quote Within 24 Hours

Email: info@celestixindustries.com

Submit Your Project Brief: Get a Quote

For custom-engineered solutions or immediate consultations, our team is ready to support your product journey from prototype to scale. Celestix brings flexibility, speed, and unmatched reliability to every project—so your harnesses perform flawlessly, every time.

Celestix Industries. Certified. Proven. Relied On.