Designing Harnesses with EMI in Mind: Shielding Strategies that Work

Introduction

In an increasingly compact and high-speed world of electronics, Electromagnetic Interference (EMI) has become a defining challenge for modern engineering. EMI directly influences signal integrity, safety, and compliance across automotive, industrial, aerospace, and medical systems.

At Celestix Industries India Pvt. Ltd., EMI control begins at the concept stage and extends throughout every phase of production — from shielding architecture and grounding optimization to simulation-driven validation. Every harness we produce is tested to meet or exceed global EMC standards, including CISPR 25, ISO 11452, and MIL-STD-461.

1. Understanding EMI and Its Engineering Impact

1.1 What Is EMI?

EMI refers to unwanted electromagnetic energy that disturbs normal circuit performance. It may be radiated through space or conducted along cables and grounding systems.

1.2 Common EMI Sources

High-frequency inverters and converters

Switching power supplies

Motors, relays, and solenoids

RF modules and antennas

Electrostatic discharge and switching noise

1.3 EMI-Related Failures

Uncontrolled EMI can degrade reliability, trigger false readings, and cause system failure — making EMI mitigation a fundamental design discipline.

2. Core Design Fundamentals for EMI Mitigation

2.1 Signal and Power Segregation

Maintain a minimum spacing of 50 mm between power and communication cables.

Use twisted pairs for CAN, LIN, and Ethernet lines.

Avoid parallel routing of high-voltage and low-signal paths.

Maintain symmetrical layouts to balance electromagnetic fields.

2.2 Grounding Techniques

2.3 Harness Routing Principles

Separate high-current and signal harnesses early in design.

Route signal cables perpendicular to power lines.

Employ metallic conduits or shielding trays in dense environments.

Use simulation tools like Ansys HFSS and HyperLynx for EMI validation.

3. Shielding Strategies That Work

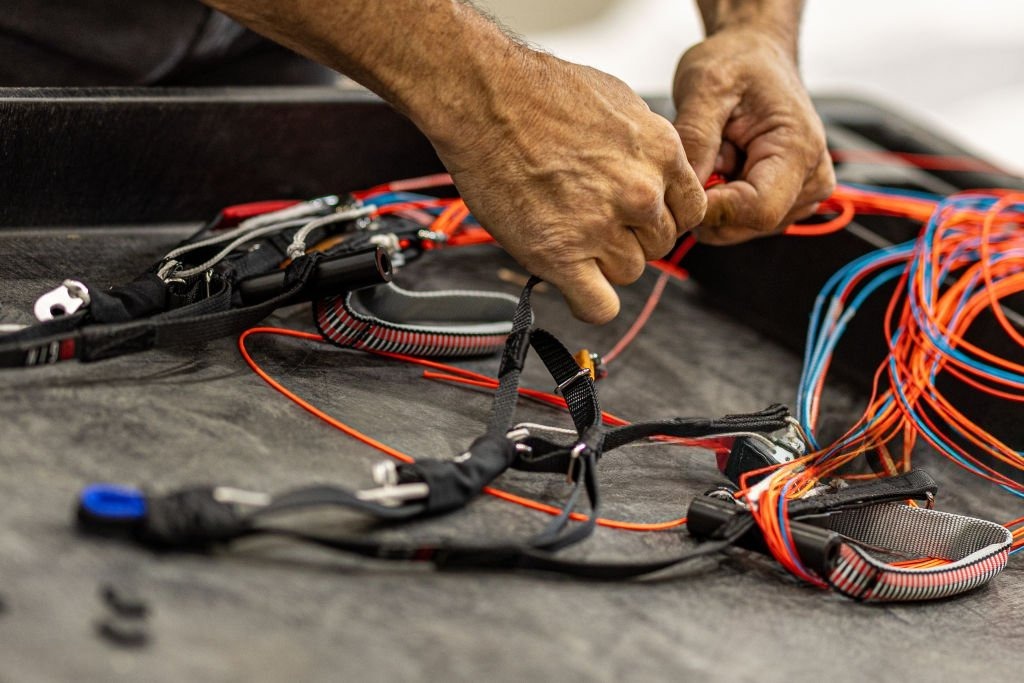

Harness shielding creates a barrier against electromagnetic noise, cutting emissions and boosting immunity — with up to 70 dB interference reduction.

3.1 Shield Termination Best Practices

Use 360° shield grounding at connectors.

Avoid pigtails — they raise impedance.

Apply conductive clamps or backshells for continuity.

Overmold connections to prevent corrosion and vibration damage.

4. EMI-Resistant Materials and Components

4.1 Conductive Materials

4.2 EMI Components

Ferrite cores absorb high-frequency interference.

Common-mode chokes reduce conducted noise.

Filtered connectors block EMI at entry points.

EMI gaskets ensure continuous conductive contact.

4.3 Insulation & Compounds

Celestix utilizes Low Smoke Zero Halogen (LSZH) and Flame Retardant (FR) compounds per IEC 62821 and ISO 6722-1 — delivering safety and EMI protection.

5. EMI Testing and Validation

The Celestix in-house EMI/EMC lab ensures compliance and reliability under real-world stress.

Harnesses are further tested for vibration, temperature cycling, and impedance stability to ensure long-term EMI resilience.

6. EMI Shielding in Electric Vehicle (EV) Applications

Electric vehicles operate under 400–800V high-frequency switching — a perfect storm for EMI. Celestix develops multi-layered harness systems designed to handle both noise and heat.

Key EV Harness Features

Dual-braided shields for traction and inverter lines

Foil underlays to reduce crosstalk.

Drain wires for stable grounding

Ferrite rings to suppress harmonics.

LSZH insulation for enhanced safety

All harnesses are certified to RoHS, REACH, and ISO 6722 standards for global export compliance.

7. Case Studies

Automotive – ADAS Radar Interference

A European OEM experienced distortion in radar signals. Celestix implemented foil + braid shielding, improving EMI immunity by 85%.

Industrial Robotics – Motion Harnesses

Spiral-shielded harnesses designed for 5 million flex cycles increased signal stability by 30%.

EV Powertrain – Conducted Noise Suppression

A domestic EV manufacturer achieved 40% EMI emission reduction with Celestix’s double-braided HV harnesses.

Aerospace – Lightweight EMI Harnessing

Nickel-copper shields provided attenuation up to 18 GHz, meeting MIL-STD-461 and DO-160 benchmarks.

8. The Celestix Advantage

Every Celestix harness is a product of engineering precision and quality control:

100% in-process and final QC

Certified under ISO 9001, IATF 16949, and ISO 14001

In-house EMI/EMC testing and overmolding

Scalable capacity for low and high-volume OEM production

Global delivery from Pune, India

Guided by DRIVE Culture — Dedication, Respect, Integrity, Value, and Excellence

9. The Future of EMI Harness Design

Harness engineering continues to evolve with AI-driven design and simulation-led optimization. Celestix R&D is pioneering:

AI-based EMI prediction for pre-production modeling

Graphene and conductive polymer shielding for lightweight efficiency

Digital twins for predictive EMI diagnostics

Nanocoatings for corrosion protection

IoT-enabled feedback systems for adaptive EMI correction

Conclusion

EMI control isn’t optional — it’s foundational. By integrating shielding, grounding, and validation throughout the product lifecycle, Celestix Industries delivers uncompromised performance, reliability, and compliance.

For OEMs seeking EMI-optimized harnesses for automotive, EV, aerospace, or industrial systems, Celestix Industries India Pvt. Ltd. is your trusted manufacturing partner.

Get in Touch

Email: info@celestixindustries.com

Request a Quote: celestixindustries.com/GetaQuote

Contact Us: celestixindustries.com/contact-us

Visit Our Facility: Pune, India — Global Shipping Available