Designing Wiring Harnesses for Extreme Environments: From Arctic Cold to Desert Heat

In the world of electrical systems, failure is not an option—especially in extreme environments where reliability is everything. From -50°C Arctic snowfields to +70°C desert installations, every connection must perform with zero compromise. In 2023, a global defense OEM operating in both Siberian cold zones and Middle Eastern deserts approached Celestix Industries with a critical challenge: engineer a single harness platform that could endure both polar frost and furnace-level heat without degradation.

This scenario highlights a growing demand across industries—from aerospace to EVs—for extreme environment wiring harnesses that offer both durability and precision. As industries expand into more challenging terrains, the role of rugged electrical connectivity becomes a strategic differentiator. At Celestix, we specialize in manufacturing custom wire harness solutions built for the toughest global conditions. Here’s how we do it.

Materials Matter: Engineered to Withstand the Elements

To deliver performance in unforgiving climates, every component of the harness—from conductor core to outer jacket—must be precisely selected and engineered. These materials are not chosen at random; they are the result of years of testing, environmental modeling, and OEM feedback.

Each material is selected not just for endurance, but for compatibility with industry-specific needs—be it aerospace weight constraints, electric vehicle fire safety standards, or mining site exposure to corrosive dust and fluids.

Pro Tip: Ask About Testing

When evaluating any extreme environment wiring harness supplier, confirm that they conduct in-house environmental testing. Celestix does—all tests are run on-site, speeding up validation and improving traceability. This also enables rapid customization and redesign based on client-specific testing protocols.

Built for Brutal Conditions: Testing That Simulates the Real World

Our harnesses are validated under the most demanding lab conditions before they ever reach the field. Every part must prove itself across mechanical, chemical, electrical, and thermal metrics. Celestix invests in this testing because we know failure in the field isn’t just expensive—it’s mission-critical.

Our key in-house testing capabilities include:

Thermal Cycling: Simulated exposure from -70°C to +150°C replicates Arctic chill and desert heat.

Salt Spray Testing: Ensures corrosion resistance per MIL-STD-810G / IEC 60068 for coastal and marine deployments.

Vibration Bench Testing: Multi-axis shock endurance testing for land-based and vehicular equipment.

Electrical Integrity: Hi-pot, resistance, and continuity testing confirm each line meets spec.

Sealing & Ingress Protection: IP66 to IP69K-level validation for water jets, dust ingress, and outdoor exposure.

Traceability: Digital batch and serial ID logging via MES integration to support compliance audits and warranty tracking.

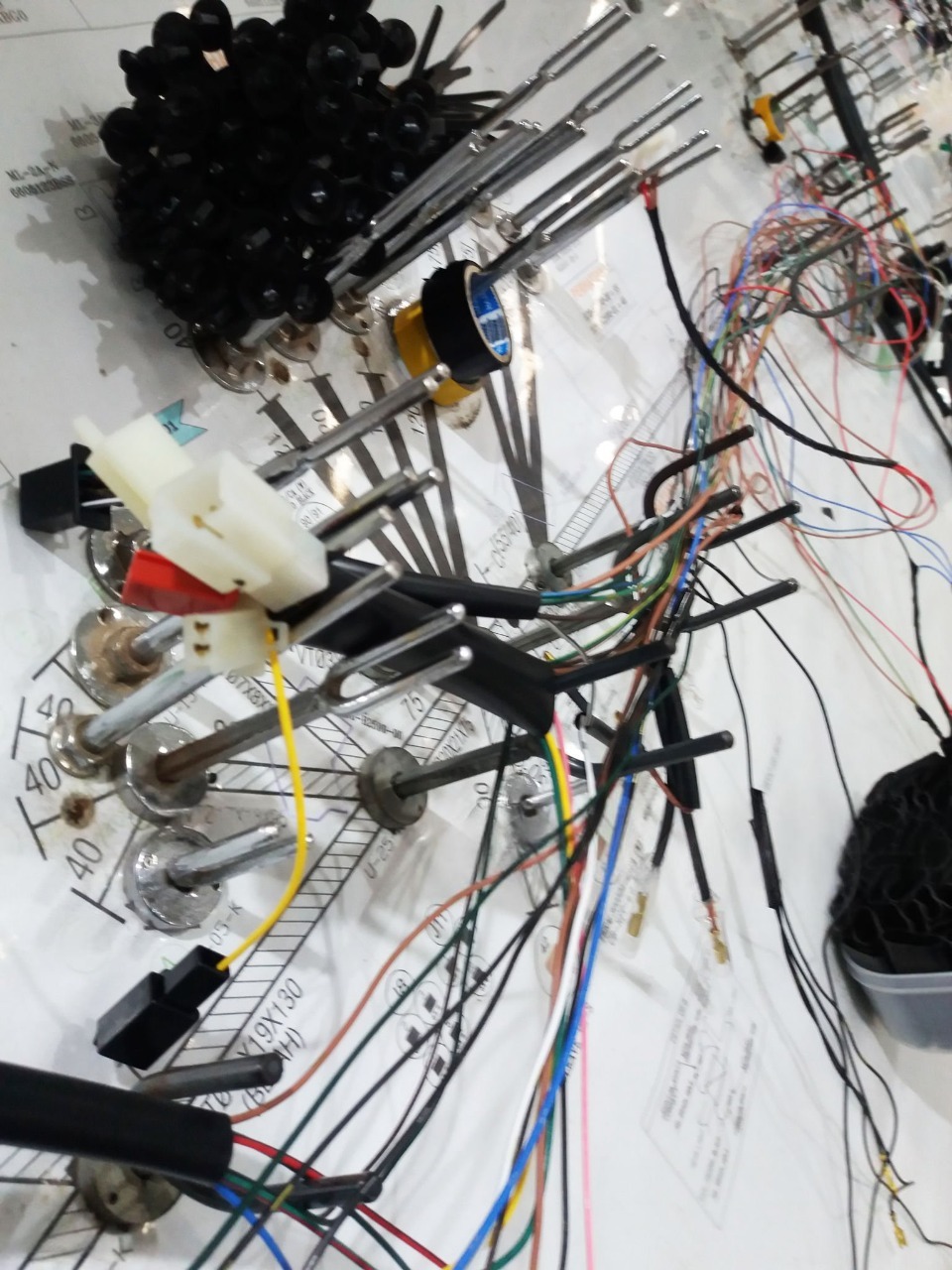

Precision at Scale: Manufacturing for Mission-Critical Markets

Whether you're launching a prototype or ramping up to full-volume production, Celestix offers manufacturing that is both scalable and tightly controlled. We use vertical integration, not third-party sourcing, to ensure consistency.

Key production capabilities:

25,000+ harnesses daily produced at our Pune, India facility

MES-integrated assembly lines allow real-time process tracking and documentation

In-process visual and automated QC checks at each phase of production

Certifications held: ISO 9001, IATF 16949 (for automotive), ISO 45001, UL, RoHS, CE, REACH, and more

Flexible production windows for small runs or high-volume JIT delivery

This makes Celestix a trusted partner for OEMs across mobility, energy, defense, and industrial sectors.

Application-Driven Design: Real-World Harness Examples

Our wiring harnesses are engineered with specific end-use conditions in mind. Below are just a few industries where Celestix solutions deliver value in extreme environments:

Each of these is customized to client drawings and supported with detailed documentation, CAD routing maps, and pinout validation reports.

Designed for the Field: Installer-Friendly Features

Technicians and field engineers regularly praise Celestix harnesses for their ease of use. Why? Because we build them to anticipate what field crews need:

Pre-labeled and color-coded connections reduce installation time and prevent errors—even in low-light or cold-weather conditions.

Modular, sealed connectors enable plug-and-play repairs in the field with minimal tools.

Pre-routed harness geometries are engineered in CAD to fit seamlessly within complex enclosures.

Installation manuals and pinout diagrams provided with every kit simplify onboarding for new crews.

Built for 10,000+ flex cycles, thanks to reinforced strain reliefs, over-molded joints, and fatigue-rated insulation.

Smart, Connected, and Field-Aware

Harnesses today are no longer passive—they’re active sensors in your system. Celestix provides embedded intelligence, particularly useful for connected EV platforms, smart UAVs, and advanced industrial IoT applications:

Integrated sensors (temperature, voltage, current) for real-time monitoring

Support for CAN/LIN, Modbus, and other industrial protocols

RFID & barcoded harness IDs allow tracking and maintenance scheduling across fleets

OTA-ready diagnostics reduce downtime by enabling early fault detection and field alerts

Did You Know?

Celestix harnesses ship globally with Kanban-ready kitting, JIT logistics, and OEM-partnered engineering support. We handle the logistics, so your team stays focused on integration and performance.

Engineered in India. Trusted Worldwide.

From our Pune-based production facility, Celestix delivers world-class harness systems to clients across Europe, Asia, and North America. What makes us different isn’t just output—it’s control:

Global fulfillment options tailored to customer timelines

Engineering and account support in your region for faster collaboration

In-house lab supports R&D, first article validation, and rapid prototyping

At Celestix, we bring together material science, field-tested validation, and scalable production to deliver wiring harnesses that thrive in extremes. Whether your product must endure desert heat or polar cold, our team builds harnesses that keep your systems moving—safely and reliably.

To explore custom harness solutions for your extreme environment application, contact our team today.