From Prototype to Production — Tailored Wire Harness Manufacturing

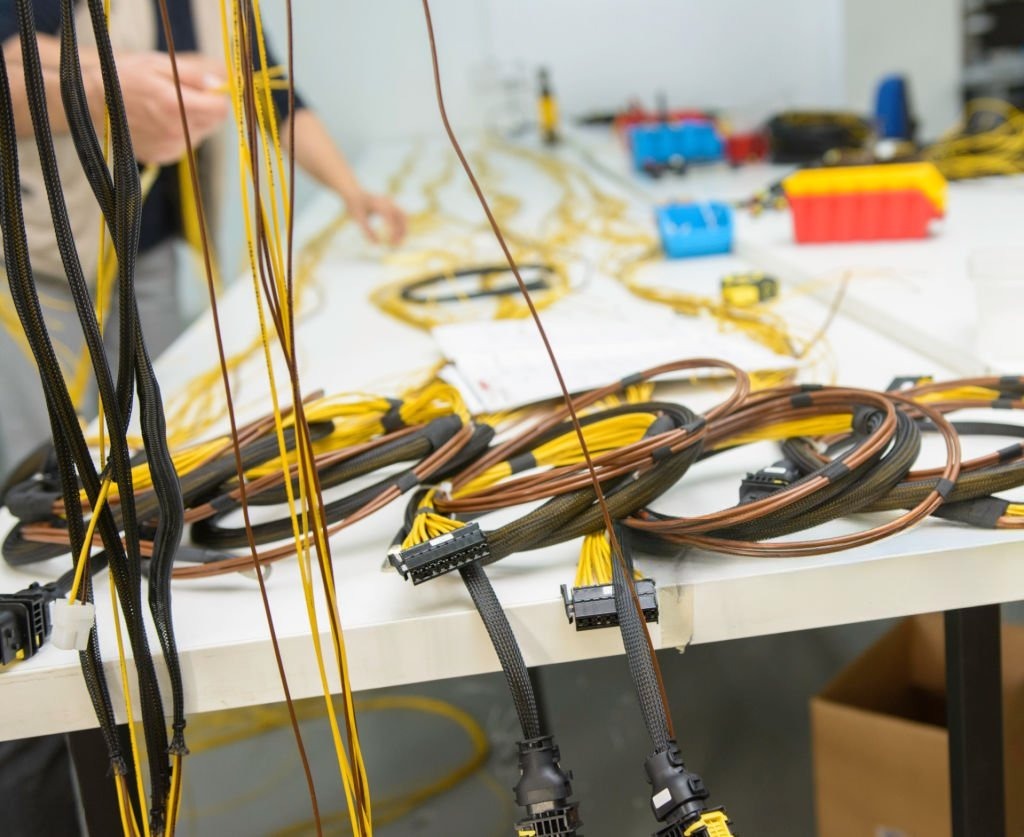

Custom wire harness manufacturing is more than bundling wires—it's engineering performance, precision, and trust into every connection. At Celestix Industries India Pvt. Ltd., we take this journey from wire harness prototype to production seriously, because our customers’ systems depend on it.

Why Tailored Wire Harnesses Matter

In modern electronics—whether it’s electric vehicles, industrial automation systems, medical equipment, aerospace, or smart appliances—a wiring harness is the central nervous system. It ensures stable power and signal transmission across critical components. A substandard harness could mean a malfunctioning BMS in an EV, interference in smart refrigerators, or downtime in robotic arms—failures that industries can’t afford.

Tailored wire harnesses go beyond one-size-fits-all configurations. They are precision-engineered to meet the demands of specific operating environments, electrical loads, and spatial constraints. For mission-critical industries, tailored solutions provide the confidence needed to scale.

From startups building their first modular wire harness prototyping to global OEMs managing complex wire harness production, the demand for tailored wiring harness solutions is growing. And with it, the need for a partner who brings technical clarity, manufacturing agility, and an unwavering commitment to quality.

That’s why at Celestix, every wire harness begins with one principle: engineering certainty into complexity.

Phase 1: Engineering the Prototype

Design for Manufacturability & Application

At the prototype stage, our engineering team works closely with your design—no matter how complex or compact. We assess:

1. Routing paths for EMI/thermal/humidity resistance

2. Material selection, including:

3. Connector layout for modularity and minimal failure points

4. Crimp profile analysis and CAD modeling using Siemens NX and EPLAN

Whether you're creating an EV wire harness prototype design, a production-ready aerospace wire harness model, or an ISO 13485-compliant medical harness prototype, our engineering process incorporates Design for Manufacturability (DFM) and Design for Assembly (DFA) principles.

Additional Design Considerations:

Poka-yoke harness assembly process

Total Cost of Ownership (TCO) analysis

Custom and gold-plated connector harness production

Stress distribution simulations using 3D CAD

Ingress protection (IP67, IP69K) considerations for harsh environments

We deliver prototypes in 1–2 weeks—optimized, testable, and scalable.

This approach supports rapid wire harness prototyping, ensuring reliability before scaling.

Phase 2: Rigorous Validation and Testing

Each prototype is validated through a rigorous, multi-point testing process:

Continuity and High-Voltage Testing (Hipot testing)

Crimp Cross-Section Analysis

Strain Relief and Pull-Force Evaluation

HALT Testing (Highly Accelerated Life Test)

Thermal Cycling, Corrosion Resistance, UV Testing

Vibration Testing for aerospace and mobility sectors

We also use digital twin wire harness design simulations to verify real-world accuracy.

Additional validation includes:

Wire Harness Failure Mode and Effects Analysis (FMEA)

Reverse Polarity Testing

Resistance and Voltage Drop Mapping

Traceability with barcoding and serialization

All validation is aligned with:

IPC/WHMA-A-620 standards

AS9100 wire harness manufacturing guidelines

ISO 13485 for medical equipment

This level of validation is critical for mission-critical applications, such as aerospace avionics, EV BMS systems, and patient-connected medical devices.

Phase 3: Production-Ready Transition

Upon validation, production ramps up using:

Automated Harness Production: Cutting, stripping, crimping, and laser marking

Robotic Harness Assembly for repeatability and quality

Advanced Overmolding & Braided Shielding for rugged environments

ERP-Based Traceability: Lot-wise data, certs, and reports

VMI Supply Chain Systems: Consistent just-in-time component flow

Applications supported:

Aluminum wire harness manufacturing

Fluoropolymer & LSZH harness production

Custom insulation protection harness manufacturing

High-temperature harness prototyping

Vibration-resistant harness manufacturing

Our processes are compliant with:

ISO 9001, IATF 16949, ISO 45001, RoHS, REACH, UL, CE, BIS, ISO 14001, ISO 6722, IEC 60228

Why Celestix?

Our commitment to quality and flexibility makes us a preferred B2B tailored harness supplier:

End-to-End Solutions: From concept to global delivery

Certified Wire Harness Prototyping: IPC, IATF 16949, UL, CE, RoHS, REACH

Custom Tooling: Molded connectors, sealed housing, overmolding

Robust Quality Control Systems: Visual, electrical, and automated

Integrated Logistics & VMI: Seamless procurement and delivery

Risk Mitigation & DFMEA: Early detection and prevention systems

Dedicated In-House Testing Lab: HALT, Hipot, Vibration, Thermal Cycle

Global Reach with Local Agility: Serving OEMs across India, Europe, and North America

Industries served:

Automotive Wire Harness Prototyping

Medical Wire Harness Manufacturing

Industrial Harness Development

Aerospace & Defense Harness Solutions

Consumer Electronics Harness Integration

Case in Point: EV Manufacturer Turnaround

Challenge: Thermal instability & EMI in EV battery harnesses

Solution:

Lightweight Al-Cu high-reliability harness

IP67-rated overmolded shielding

Optimized CAD layout via EPLAN tools

Rapid deployment within 5 weeks

Results:

20% faster charging

15% lighter harness

100% traceability for compliance

The Future of Harnessing Innovation

Celestix continues to invest in:

Smart Harnesses with embedded sensors

AI-driven Quality Control

Digital Twin Prototyping & Simulation

Expanded Automation for scalability

Green Manufacturing aligned with RoHS, REACH, and ISO 14001

Advanced CAD Tools like Siemens NX, EPLAN, and AutoCAD Electrical

Predictive Maintenance via Data-Enabled Harness Systems

Scalable, modular harness platforms for multiple SKUs

Whether you need:

IP67 automotive cable assemblies

PTFE aerospace wiring solutions

ISO-certified medical-grade wiring

High-density industrial wire looms

Ready to Start?

Let’s take your concept from prototype to production with unmatched quality, reliability, and speed.

Email Us: info@celestixindustries.com

Request a Quote: celestixindustries.com/GetaQuote

Visit Us: Pune, Ahmedabad, Greater Noida — serving global OEMs with scalable precision

Have Questions? Our engineering team is ready to guide you through DFM options, alternative materials, or rapid turnaround prototyping, tailored to your specific timeline.

Need It Fast? We support urgent builds with dedicated rapid-response manufacturing cells.

Want to Validate First? Request a prototype with full test documentation, traceability, and compliance reports.

Celestix Industries — Engineered to Perform. Built to Last.