Harness Innovation: Streamlined Wiring for Modern Assemblies

“Modern wiring harnesses aren’t just components—they’re the nervous system of every advanced machine.”

— Lead Systems Engineer, Celestix Industries

Redefining the Backbone of Modern Machines

In the age of high-performance electric vehicles, intelligent automation, and smart appliances, wiring harnesses are more than just wire bundles—they’re engineered lifelines. At Celestix Industries, we manufacture custom wiring harnesses that power modern technologies with precision, performance, and reliability.

We apply DFMA principles and design for reliability right from the blueprint phase—ensuring every modern assembly is optimized for function, cost, and manufacturability. Our solutions are trusted across sectors, including EV applications, aerospace harnesses, medical devices, and smart consumer products.

Why “Streamlined” Wiring Isn’t Just a Buzzword

Streamlined design in wiring harness manufacturing isn't about cutting corners—it’s about reducing complexity without sacrificing integrity. Engineers know: fewer components mean fewer failure points, lower weight, and faster installation. In industries like automotive, industrial automation, and telecom, this translates to real-world gains in efficiency, safety, and serviceability.

Streamlined wiring = better reliability + faster production + leaner systems.

Key Advantages of Streamlined Harnessing

Weight Reduction – Especially critical for EVs and aerospace applications

Improved Reliability – Fewer junctions = fewer potential faults

Faster Assembly – Pre-configured harnesses reduce line time by up to 30%

EMI Shielding – Better shielding layouts minimize signal interference

Routing Optimization – Cleaner routing enhances thermal and signal performance

Engineering Streamlined Excellence at Celestix

Our approach integrates modular assemblies, Poka-Yoke techniques, and assembly automation backed by IPC standards and global ISO certifications. Here's how we build smarter:

1. Advanced Material Selection

We choose high-conductivity copper conductors, lightweight aluminum wiring, and durable insulation materials such as PVC sheathing, XLPE insulation, and PTFE durability coatings. These materials are selected based on specific application environments.

2. Automation Tools That Scale

We leverage:

Crimping Technology – Automated presses for consistent crimp force and shape

Ultrasonic Welding – Strong, solderless connections for signal and power wires

CAD Software – 3D harness design and digital validation

Virtual Prototyping – Simulation of current, voltage drop, and bend radius

Rapid Prototyping – Fast turnaround on concept validation

3. Design Optimization Through CAD

Using leading CAD software, we integrate:

DFM input to prevent over-engineering

Strain relief mechanisms to protect terminations

Digital twins to map layout and perform tolerance analysis

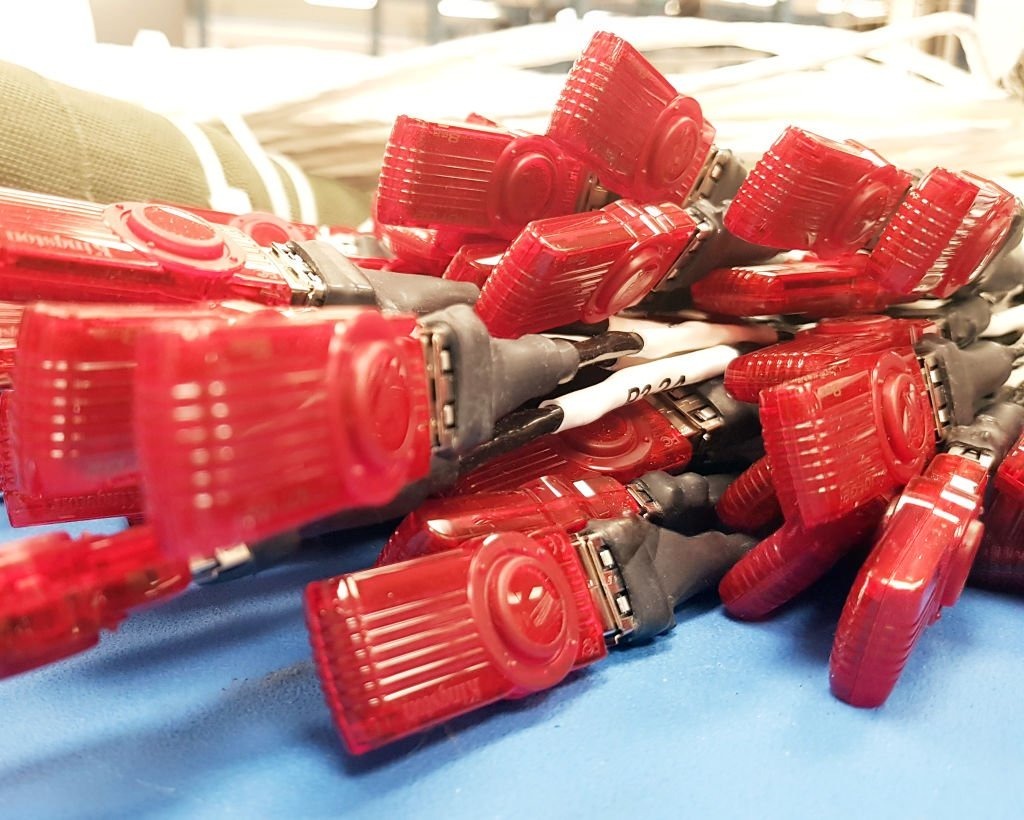

4. Innovative Connector Engineering

We incorporate:

Connector innovation with sealing, alignment, and multi-lock features

Terminal plating including gold contacts for high-cycle performance

Color coding and Poka-Yoke design to eliminate assembly errors

Rigorous Testing and Quality Control

Each wiring harness undergoes:

Continuity Testing – Ensures correct routing

Hipot Testing – Validates insulation resistance

Vibration Resistance – Simulates road or machine movement

Thermal Cycling – Verifies behavior in extreme temperatures

IP Ratings Compliance – Ensures water and dust protection

Ensuring Long-Term Reliability

We maintain precise reliability metrics and conduct failure mode analysis across all project phases. Our test standards align with:

Quantifiable Results

Our harnesses demonstrate a 22% lower failure rate under vibration compared to standard OEM benchmarks.

Thermal aging tests show lifespan performance exceeding 2000 cycles without degradation.

For one EV OEM, we achieved a 12% overall weight reduction by switching to hybrid aluminum-copper conductors.

In industrial automation applications, streamlined assemblies reduced field installation time by 28%.

Industry Applications of Streamlined Wiring Harnesses

1. Automotive & EVs

Advanced harnesses manage everything from powertrains and ADAS to infotainment and battery packs. Celestix supports OEMs with high-voltage, EMI-shielded, and weight-optimized harnesses.

2. Aerospace & Defense

We deliver ultra-reliable harnesses with flame-retardant PTFE, gold-plated contacts, and IP-rated connectors for vibration-heavy, altitude-sensitive systems.

3. Medical Devices

Precision wiring solutions power life-saving equipment like patient monitors, ventilators, and MRI systems—where compliance, sterility, and safety are non-negotiable.

4. Industrial Automation

Harnesses for robotics, CNC machines, and sensors require high-flex cables, chemical-resistant sheathing, and modular design for scalable deployment.

Certifications & Compliance Confidence

Every harness is built to exacting international standards. Our certifications include:

We undergo periodic audits, third-party inspections, and rigorous internal validation to ensure full traceability, reliability, and environmental responsibility

Our Harness Development Workflow

Customer submits specifications or harness drawings

The Celestix engineering team reviews and provides DFM input

CAD layout and digital twin simulation for routing and performance

Prototype development and internal testing (continuity, pull-force, hipot)

Customer validation and approval (FAI or PPAP as needed)

Pilot production run

Full-scale production with in-process quality checks

Final testing, packaging, and global shipping

Customer-Centric Engineering

Celestix thrives on supplier collaboration and customization value. We understand buyer psychology and the need to reduce risk, cost, and uncertainty. Our clients benefit from:

Early DFM input and design support

Risk mitigation through multiple sourcing and safety stock

Real-time dashboard updates and reporting

Emphasis on total cost ownership, not just unit economics

Deep experience that strengthens brand reputation

Real-World Innovation: From Smart Appliances to High-Voltage EVs

For a global appliance manufacturer, we solved condensation failures using IP67-rated over-molded connectors and EMI shielding. In the EV sector, we engineered a braided high-voltage harness using aluminum-copper hybrid conductors, boosting performance and cutting weight.

From Prototypes to Production—We Deliver

We support projects from prototyping efficiency all the way to mass production. With proven scalability, risk mitigation strategies, and supply chain resilience, we serve customers globally while maintaining 100% on-time delivery.

Take the First Step Toward Smarter Electrical Integration

Whether you're refining a legacy product or launching the next innovation in EV or aerospace, Celestix helps you streamline innovation with engineering precision.

Contact our experts at: info@celestixindustries.com

Or accelerate your project today: Request a Quote

Celestix Industries: Engineered Wiring, Built for What’s Next.