Harnessing Performance: What Makes Automotive Wiring Survive 10,000 Cycles

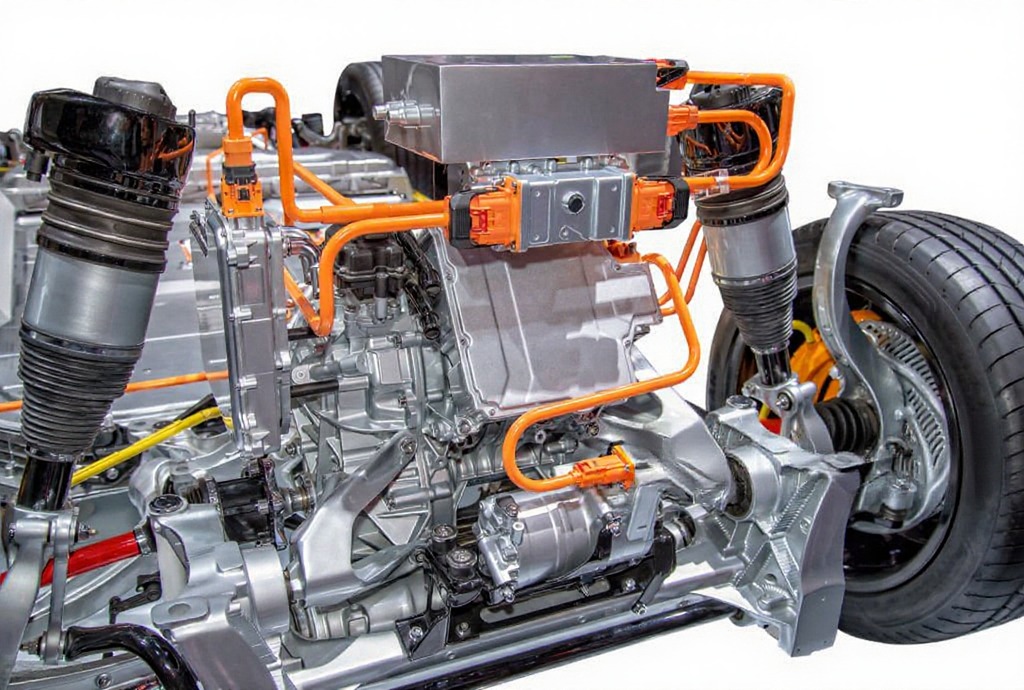

In the fast-evolving world of automotive engineering, every component must perform reliably under extreme conditions—none more so than the automotive wiring harness. With the rise of electric vehicles (EVs), ADAS systems, and connected car platforms, the humble harness is no longer just a wire bundle—it’s a mission-critical system that must endure 10,000+ flex cycles, intense vibrations, extreme temperatures, and corrosive environments.

So, what makes a wiring harness capable of surviving 10,000 cycles—or more? At Celestix Industries, we engineer for durability, safety, and electrical integrity from the ground up. In this guide, we explore the core design, testing, and manufacturing elements behind automotive wiring harness durability, optimized for longevity and real-world resilience.

1. Material Science: Engineering from the Core

“The lifecycle of a harness starts long before it’s installed in a vehicle. It begins with the selection of conductor and insulation materials that can tolerate stress, flex, and heat for years. We don't just meet standards—we exceed them to futureproof designs for next-gen platforms.”

Understanding what goes into a high-cycle wiring harness starts at the material level. The performance and longevity of the system depend heavily on the conductor and insulation materials used. These must not only conduct electricity but also withstand high-frequency movement, heat, and corrosive environments over many years.

Common Conductor and Insulation Materials

Key Takeaways

Optimized conductor materials such as tinned copper and hybrid aluminum-copper, are critical for performance and corrosion resistance in high-cycle environments.

Our insulation materials—including XLPE, PTFE, and LSZH—are selected to meet demanding automotive environments.

All selections are backed by strict adherence to international standards: ISO 6722, SAE J1128, and UL/CSA, ensuring long-term compliance and safety.

2. Mechanical Endurance: Built for Flex and Fatigue

“When a customer specifies 10,000 cycles, we build for 12,000. Overengineering is how we deliver confidence. Cycle fatigue, crimp integrity, strain isolation—it all comes down to how you route, secure, and reinforce the harness mechanically.”

Dynamic automotive zones—like doors, tailgates, seats, and steering columns—are subjected to repeated mechanical movements. Without robust mechanical design, conductors can fracture, insulations can crack, and terminals can disconnect.

Celestix deploys proven design strategies to maximize the endurance of every harness.

Endurance Design Tactics

Flex Testing Standards: EN 3475-512 Flex Cycle Test • ISO 19642 Tensile Strength Verification • >10,000 Flex Cycles Validated

These standards simulate real-world cycling and allow engineers to predict mechanical failure modes in the design phase. They also help in benchmarking performance against industry norms, giving OEMs confidence in long-term performance.

Goal: Pass wiring harness fatigue testing and survive 10,000+ dynamic movements.

3. Process Precision: Crimping, Over-Molding & Error-Proofing

Beyond design, manufacturing execution determines reliability. Even the best design will fail if manufactured inconsistently.

At Celestix, automated equipment, poka-yoke processes, and error-proofing mechanisms ensure every crimp, cut, and seal meets the tightest tolerances.

Top Process Features

Automated Crimping with in-line crimp force analysis

Cross-section inspection after every tool change

Precision Over-molding for IP69K-rated connections

Color-coded and key-coded assemblies for error-free installation

Process Monitoring:

IPC/WHMA-A-620 Class 3 Compliance

SPC Quality Control Metrics

Contact Resistance < 10 mΩ

With our end-to-end digital traceability, we ensure no component or assembly escapes quality checkpoints. These processes ensure that from prototype to mass production, every harness delivers repeatable, reliable quality.

4. Environmental Shielding: Ready for the Road

Modern vehicles traverse deserts, snowfields, salt-laden coastal areas, and industrial cities. Wiring harnesses must be shielded and sealed to survive it all.

At Celestix, every harness is designed for the environment it operates in, whether it’s under the chassis or near high-heat engine zones.

Environmental Protections by Application

Proven Against:

IP68/IP69K water ingress protection

85°C, 85% RH, high humidity storage and operation

Automotive harness thermal cycling, salt spray, and mud baths

These techniques extend the harness life and reduce the need for early replacement or costly service campaigns. Environmental resilience is not just a feature—it’s a non-negotiable requirement for global deployments.

5. Rigorous Testing: Where Failure is Not an Option

“In harness validation, there’s no room for assumptions. We replicate thermal shock, ingress, vibration, and high-voltage conditions that would typically take years to appear in the field—all within weeks of testing.”

No matter how advanced a harness appears on paper, validation testing is the only proof of reliability. At Celestix, every harness design is validated with extensive mechanical, electrical, and environmental testing.

Key Testing Areas

Electrical Testing: Continuity, Hipot, Insulation Resistance

Mechanical Testing: Tensile strength, Crimp Pull Force, Flex Cycle Endurance

Environmental Testing: Thermal shock, salt fog, vibration, HALT/HASS

Test Standards Applied:

ISO 6722, ISO 19642 (Automotive wiring)

EIA-364, IPC-TM-650 (Electrical connection validation)

IEC 60512, SAE J2030 (Durability, vibration, and ingress testing)

Testing is conducted both in-house and at certified third-party labs. Our lab and inspection capabilities are continuously calibrated and certified, ensuring repeatable accuracy and traceable results.

6. Manufacturing Scale, Agile Support

Reliability means nothing without availability. We support high-mix, high-volume harness production with:

Manufacturing Capabilities

Supporting:

Just-in-Time (JIT) delivery

Vendor-Managed Inventory (VMI)

Engineering change tracking

Forecasted scheduling and global shipping

Our production facilities in Pune are strategically located to serve both domestic and international clients. Celestix is structured to deliver scalability without compromising custom engineering attention.

Conclusion: Built to Last, Engineered to Perform

The expectation for modern automotive wiring harnesses is nothing short of excellence. Whether for an electric vehicle, an autonomous system, or a performance combustion engine, the demand is the same: survive 10,000+ cycles without failure.

At Celestix Industries, we combine decades of engineering knowledge with modern manufacturing technology to deliver:

High-cycle automotive wiring harness designs

Automotive wiring quality control is built into every stage

DFM and DFA-optimized assemblies

Compliance with global standards (IATF 16949, ISO 14001, IPC/WHMA-A-620, UL/CE/BIS)

Partner with Celestix for unmatched performance, reliability, and compliance in every harness.

Email: info@celestixindustries.com

Quote Form: celestixindustries.com/GetaQuote

For technical documentation, PDF downloads, product demos, or co-branded brochures, reach out today.