How Celestix Helped an EV Manufacturer Improve Battery Performance

Introduction

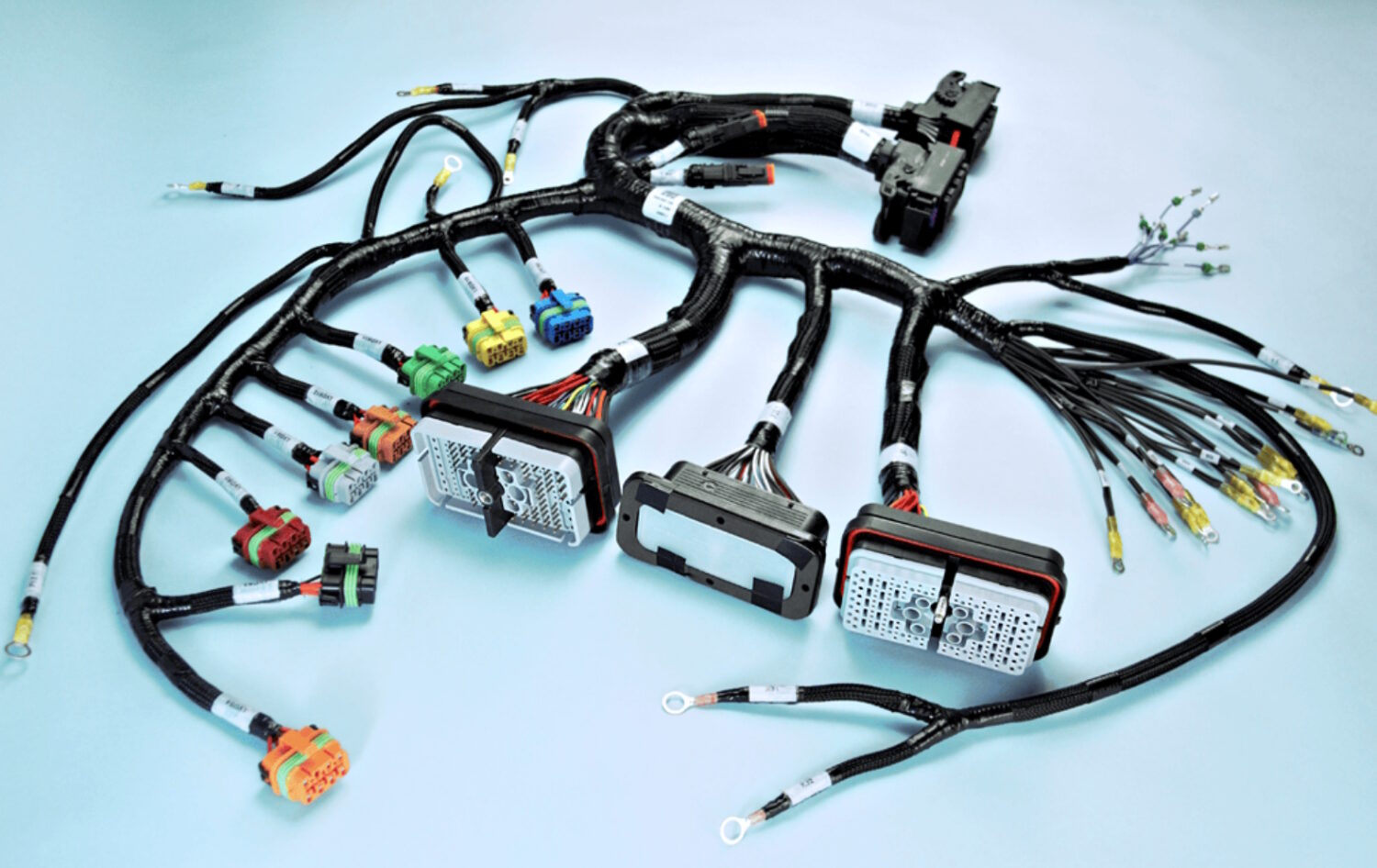

Electric vehicles (EVs) rely on high-voltage wiring harnesses for efficient power transmission and battery management. A leading EV manufacturer approached Celestix Industries with a critical challenge: their existing battery wiring harness was causing voltage drops, overheating, and EMI interference, leading to power inefficiencies and performance inconsistencies.

Celestix worked closely with the client to redesign their high-voltage wire harness, incorporating advanced materials, optimized shielding, and improved conductor layouts. The result? A 20% increase in charge efficiency, reduced heat generation, and improved safety standards. Let’s explore how we solved this challenge.

The Challenge: Performance Limitations in EV Battery Harness

The client’s existing high-voltage harness faced the following issues:

- Voltage drops under high load conditions, reducing power efficiency.

- Electromagnetic interference (EMI) affecting motor performance and onboard electronics.

- Overheating issues, leading to potential safety hazards.

- Bulky wiring configurations, affecting vehicle weight and space optimization.

- Inconsistent fast-charging efficiency, slowing down charging cycles.

With EV range and charging time being critical factors, they needed a solution that would enhance power delivery, optimize safety, and improve charging efficiency.

Celestix’s Solution: A High-Performance EV Wiring Harness

To overcome these challenges, Celestix developed a custom-engineered high-voltage wiring harness with the following enhancements:

1. Advanced Conductor Material for Optimal Power Flow

- Implemented lightweight aluminum-copper hybrid conductors to reduce weight while maintaining conductivity.

- Optimized conductor strand size to minimize resistance and voltage drop.

2. EMI Shielding for Improved Signal Integrity

- Added multi-layer braided shielding to eliminate EMI and ensure stable power transmission.

- Introduced twisted-pair configurations for noise reduction in sensitive circuits.

3. Heat-Resistant Insulation for Enhanced Safety

- Used flame-retardant silicone and Teflon insulation to withstand high operating temperatures.

- Designed over-molded connectors with thermal-resistant materials for durability.

4. Optimized Wire Routing for Space Efficiency

- Redesigned the harness layout for better cable management and reduced bulk.

- Utilized flat cable structures for tight space applications.

5. Fast-Charging Optimization for Battery Efficiency

- Implemented low-resistance conductor pathways to improve charge rate efficiency.

- Reduced heat build-up in high-current pathways, increasing charging safety.

The Results: A Game-Changer in EV Performance

Following Celestix’s solution, the EV manufacturer experienced significant performance gains:

✅ 20% improvement in charge efficiency, allowing for faster charging cycles. ✅ Voltage stability increased by 15%, reducing power fluctuations. ✅ EMI interference eliminated, ensuring smooth operation of onboard electronics. ✅ 50% reduction in overheating issues, enhancing safety and battery life. ✅ Overall weight reduction, improving EV range and energy efficiency. ✅ Compliance with ISO 26262, UL 94V-0, and other global safety standards.

Why Celestix is the Preferred Partner for EV Wiring Harnesses

Celestix Industries specializes in high-voltage wire harness solutions tailored for EVs, hybrids, and next-generation automotive applications. Our expertise includes:

✅ Custom-engineered wiring solutions for battery management systems, charging infrastructure, and power distribution.

✅ ISO 9001 & IATF 16949-certified manufacturing for premium quality assurance.

✅ In-house EMI shielding and thermal testing to guarantee reliability.

✅ Scalable production capabilities to support both prototyping and high-volume production.

✅ Integration of advanced materials to improve durability, conductivity, and efficiency.

With EV technology evolving rapidly, Celestix remains at the forefront, delivering next-generation wire harness solutions that maximize power efficiency and safety.

Need a high-voltage wiring solution for your EV application? Contact Celestix today for custom-engineered, high-performance wire harnesses.