How Certified Harnesses Reduce Your Product Recall Risk by 30%

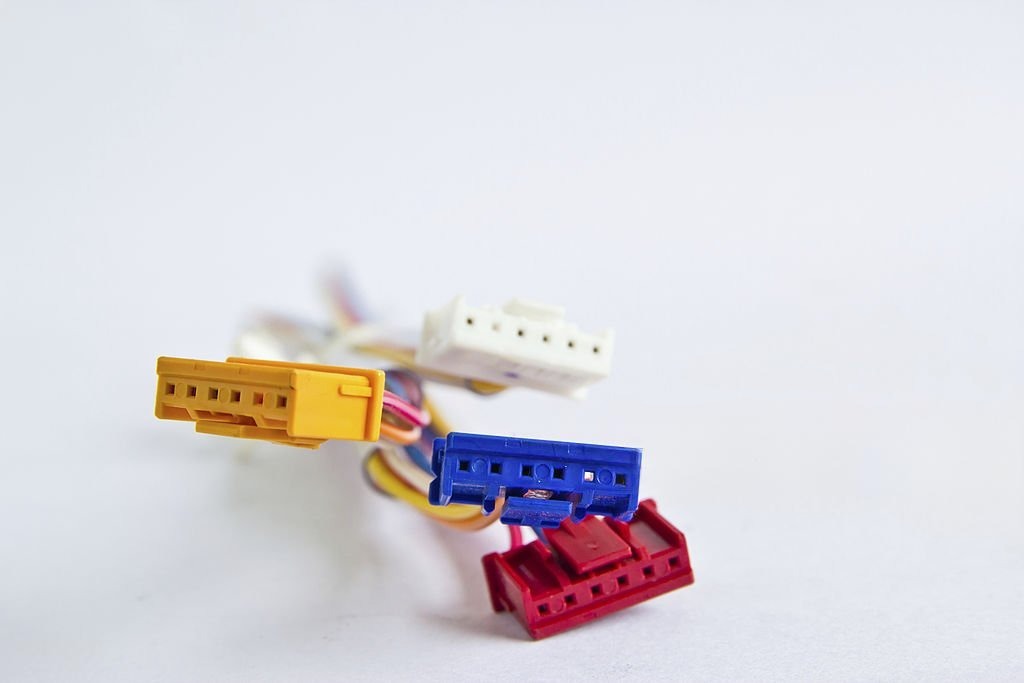

In manufacturing, product recalls are a nightmare—costly, damaging, and often avoidable. One frequently overlooked source of failure? Substandard wiring harnesses. These critical components form the nervous system of any electrical assembly, and a single defect can cascade into widespread product failure. At Celestix Industries, we’ve seen how integrating certified wiring harnesses directly contributes to a measurable 30% reduction in recall risk.

Why It Matters

Let’s explore how—and why—certified harnesses drive real-world reliability with measurable, bottom-line benefits for your business.

1. Why Recalls Happen: The Wiring Harness Weak Link

Common Failure Points

These wiring harness failure modes often stem from poor quality control, such as skipped inspections, non-conforming crimps, or improper assembly documentation.

Quality Control Spotlight

Lack of continuity checks can lead to undetected open circuits.

Inconsistent insulation stripping or crimping causes weak electrical connections.

Missing documentation limits traceability during a failure investigation, which can severely delay root-cause analysis and corrective actions.

In mission-critical applications—such as those in the automotive, aerospace, and medical device industries—even a single flaw can escalate from a nuisance to a hazard.

As electrical systems grow increasingly complex, the demand for electrical safety harnesses and designs optimized for reliability grows in parallel. Without standardized components and robust harness manufacturing quality practices, manufacturers face escalating risks.

2. Certified Harnesses: Your First Line of Defense

Celestix-certified harnesses are designed to meet the highest international wiring harness standards, ensuring consistent, defect-free performance.

Key Certifications (with Functional Relevance)

ISO 9001 – Standardized quality management system across manufacturing operations

IATF 16949 – Automotive-specific quality assurance with built-in risk and defect control

IPC/WHMA-A-620 – Global standard for cable and wire harness workmanship

AS9100 – Aerospace-grade safety, traceability, and process discipline

ISO 13485 – Medical device compliance for electrical safety and cleanliness

UL/CSA Certification – International safety certification for consumer and industrial markets

RoHS & REACH – Regulatory compliance ensuring materials are safe and sustainable

MIL-DTL-3885G – Military durability standards for rugged environments

Certified harnesses offer:

Confidence in validated material, process, and final product reliability

Simplified audits and faster product certifications

Clear traceability, enabling better lifecycle risk management

Fewer post-sale failures and reduced liability exposure

3. Engineering-Grade Quality Control

Celestix harnesses are tested under a robust quality assurance regimen, ensuring long-term reliability.

Quality Control Checklist

Continuity Testing – Confirms electrical connectivity and detects open circuits or shorts

Hipot Testing – Assesses insulation strength under high voltage conditions

Pull Force Testing – Validates the mechanical integrity of crimps and terminations

Crimp Cross-Section Analysis – Examines the internal structure of each crimp for compression and coverage

EMI/RFI Shield Testing – Measures shielding effectiveness in signal-critical applications

Environmental Stress Screening – Simulates thermal, humidity, and vibrational stresses

Insulation Resistance Testing – Evaluates dielectric properties to prevent current leakage

Torque and Lock Retention Testing – Ensures secure mating and latching of connectors under strain

These tests are designed not just to meet, but exceed, industry norms—making harness failure prevention part of our core deliverables.

4. Statistical Evidence: 30% Recall Risk Reduction

Performance Metrics (Based on Client Benchmarks)

These figures validate the impact of certified harness suppliers like Celestix in real-world deployments.

5. The Real Cost of a Recall—and How Certification Saves You

Financial Impact of a Recall

By mitigating defects at the source, certified harnesses offer both cost avoidance and peace of mind.

6. Celestix Certified: Built Right, Built to Last

Our Quality Framework

Built under Six Sigma – Ensures statistical control and minimal variance

Tested to IPC/WHMA-A-620 Class 3 – The highest level of acceptance for mission-critical applications

ISO-Certified Production Cells – Process validation across automotive, medical, and aerospace standards

In-House Test Laboratory – Equipped for dielectric, resistance, and lifecycle simulations

Additional Capabilities

Rapid Prototyping – 7–10 day cycle for validated pre-production samples

Volume Flexibility – From pilot to mass production, with zero change in quality

Component-Level Traceability – Serialized tracking across wires, terminals, and subassemblies

Regulatory Documentation Packages – PPAP, FAI, control plans, and inspection records

7. What to Look for in a Certified Harness Partner

Evaluation Checklist for Strategic Sourcing

Celestix Industries meets and exceeds each of these criteria, helping customers scale with confidence.

Final Word: Let Certification Protect Your Product

When quality, safety, and your reputation are on the line, certification isn’t optional—it’s your first layer of defense.

Choosing Celestix means choosing:

Fewer warranty claims through upstream defect elimination

Faster audits and simplified regulatory approval

Lower operational risk with predictable product performance

Proven cost savings through fewer recalls and higher reliability

Don’t wait for a costly failure.

Choose quality at the source and safeguard your reputation, customer satisfaction, and bottom line. Let Celestix certified harnesses give your product the assurance it deserves—from prototype to production.

Built-in reliability from the start—choose certified wiring harnesses from Celestix.

Contact Us:

Email: info@celestixindustries.com

Quote Form: Request a Quote