Reduce Downtime with Robust Wire Harness Solutions

In high-demand industries like automotive, industrial automation, aerospace, and EVs, equipment downtime isn’t just a nuisance—it’s a direct hit to productivity and profitability. At Celestix Industries India Pvt. Ltd., we engineer robust wire harness solutions specifically designed to eliminate preventable failures, optimize uptime, and meet the demanding standards of mission-critical applications.

1. The Hidden Cost of Downtime

Unplanned downtime can cascade into severe operational and financial losses. Whether it's an automotive assembly line grinding to a halt or a smart appliance failing post-installation, the disruption reverberates across production, logistics, and customer trust. The cause? Often, a single, overlooked failure point: a poorly manufactured wire harness.

Our prospective clients can trust us to reduce downtime with wire harnesses engineered for consistency, resilience, and compliance. By focusing on wire harness reliability, durable wiring harnesses, and failure prevention, Celestix mitigates risk where it matters most.

Downtime doesn’t just disrupt processes—it creates ripple effects that impact supply chain commitments, customer satisfaction, and maintenance budgets. That's why OEMs and industrial leaders must prioritize proactive wire harness maintenance and invest in reliable cable assemblies that stand the test of time.

“In India’s monsoon-heavy climate, even minor insulation breakdowns can trigger catastrophic electrical failures. At Celestix, we build with that level of risk in mind.” — Lead Design Engineer, Celestix

Common Downtime Drivers from Faulty Harnesses

2. Engineered for Reliability from the Ground Up

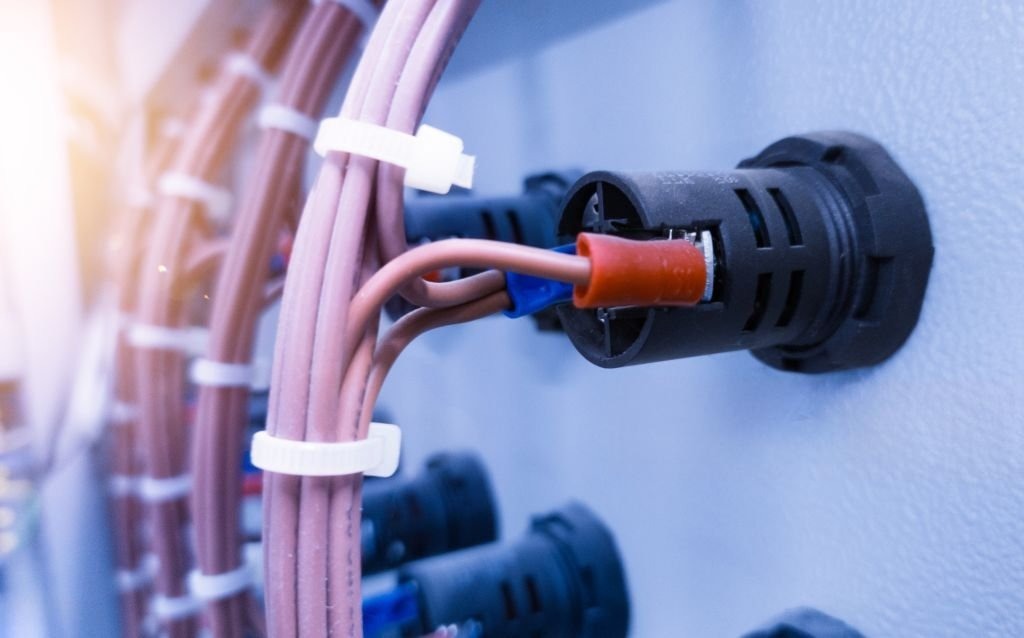

At Celestix Industries, every wire harness is built on a foundation of Design for Reliability (DfR) and Design for Manufacturability (DfM). Our experienced engineering team evaluates each harness for mechanical strength, thermal resistance, EMI shielding, and chemical durability. We use:

High-purity copper and aluminum-copper hybrids

Class K fine stranding for flexibility

Insulation materials like PVC, Teflon, XLPE, and silicone

IP67/IP69K over-molded connectors

We don't just build to spec—we build for extended service life in extreme conditions. Each harness is engineered for heat resistance, vibration tolerance, and environmental durability, especially under the challenging environmental factors common across India's industrial hubs.

“Whether you’re operating in the dry heat of Nagpur or the salty air of coastal Gujarat, our harnesses are built to last.” — Quality Control Manager, Celestix

Industry Certifications We Comply With

We also offer custom wire harness manufacturing backed by CAD, simulation, and digital twin wire harness development for optimization and failure prevention.

3. Failure-Proofing with Comprehensive Testing

We believe wire harness quality control is a critical investment—not an afterthought. Every wire harness is subjected to:

100% Continuity Testing

High-Voltage Dielectric (Hipot) Testing

Crimp Pull Force Verification

Environmental Simulation (ISO 16750 standards)

Impedance & Insulation Resistance Testing

Tensile Load and Crimp Section Analysis

Each of these steps aligns with Celestix's commitment to zero-defect manufacturing. From raw material inspection to final product validation, our multilayered quality gates ensure that every harness can withstand the rigors of real-world usage.

4. We Invite You to Partner With Us

We are actively seeking partnerships with innovative startups, emerging OEMs, and growing manufacturers who need a reliable, responsive, and technically sound wire harness supplier.

Whether you're developing a new EV platform, launching industrial automation systems, or building smart devices, Celestix provides:

Quick-turn prototyping for pilot projects

In-house lab testing to validate your design

Scalable manufacturing as your production grows

Complete documentation for the investor and certification readiness

Our goal is to support your success from concept to launch. Partner with us on a pilot project or first-run build—and see why flexibility, quality, and collaboration are the cornerstones of everything we do.

Let’s build something reliable—together.

Explore a first-time trial order or request a design consultation—no long-term commitments needed to get started.

5. Built for Scale, Ready for Urgency

Celestix is built to adapt—whether you’re scaling up from 100 units to 10,000 or managing urgent builds for last-minute production requirements.

Our Pune facility is optimized for flexibility and response. We don’t just produce wire harnesses—we engineer confidence into your production schedule.

If you're preparing for a product launch or responding to time-sensitive customer demand, we’re the wire harness partner that can keep up.

Contact Celestix Today

Email Us: info@celestixindustries.com

Request a Quote: Get a Quote

Contact Form: Contact Us