Seamless Integration Starts with Superior Harness Design

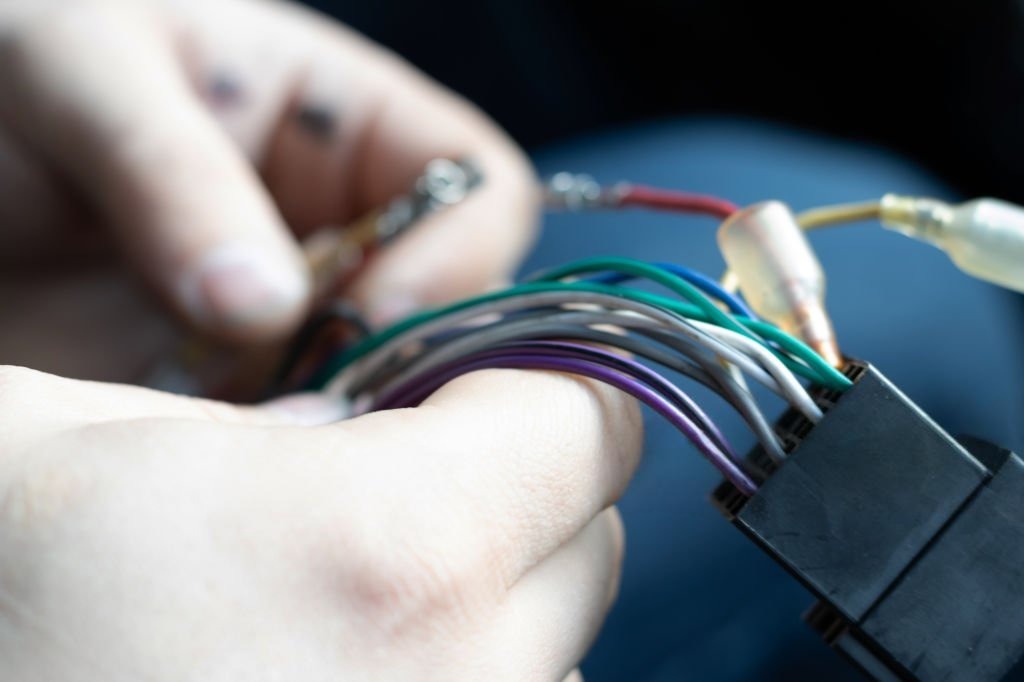

In a world driven by electrification, automation, and miniaturization, wiring harness design isn’t just about connectivity—it's the foundation for superior harness integration. At Celestix Industries, we engineer application-driven designs tailored for industry-specific integration needs. Our solutions power systems that demand uncompromising reliability, performance, and flexibility.

Whether for automotive wiring harness systems, aerospace-grade assemblies, medical device solutions, or industrial automation, Celestix delivers custom wiring harness manufacturing with proven reliability, compliance, and performance. Our commitment to engineering excellence ensures every connection supports scalable innovation and long-term success.

The Engineering Mindset: Design is Everything

Modern systems require precision-engineered harnesses that:

Harness design is not just a pre-production step—it’s a foundation for product longevity and integration stability. Every harness is an opportunity to optimize performance, reduce complexity, and preempt field failures.

Common Harness Integration Challenges (And How Celestix Solves Them)

Misrouted harnesses — solved by color coding, 3D visual routing, and clamps.

Overheating insulation — addressed with thermal cycling and derating checks.

Unreliable crimps — eliminated via inline crimp force monitoring and pull tests.

Length inaccuracies — prevented using digital cut-length validation.

EMI issues — solved with integrated shielding and zone planning.

We design with the end-user, assembly technician, and maintenance engineer in mind. This leads to reduced installation times, minimized error potential, and faster field servicing.

Material Mastery: Selecting the Right Components

We engineer with a focus on material compatibility, using:

Celestix harnesses are built with precision—from conductor strand count to insulation thickness and crimp pull force tolerance. Materials are selected for mechanical performance, regulatory compliance, and long-term reliability.

We offer copper conductor harnesses for high current and signal clarity, aluminum alternatives for lightweight builds, and PTFE insulation for high-temperature or chemical environments.

Quality Control at Every Stage

We embed quality assurance into every manufacturing stage. Each wire, crimp, and connector is validated through automated testing platforms. From cable prep to final overmolding, nothing leaves our facility without certification-ready documentation.

Celestix is certified to IATF 16949, AS9100, ISO 9001, and follows IPC/WHMA-A-620 workmanship standards. We incorporate digital QMS, traceability tracking, and closed-loop feedback systems.

Smart Tools & Rapid Prototyping

Our digital-first process reduces delays, accelerates iteration cycles, and improves launch timelines. In regulated industries, we assist with FAI (First Article Inspection), DVP&R, and even PPAP-level documentation for automotive applications.

Built for Every Industry

Our engineering team is experienced in adapting harnesses to extreme environments, stringent regulatory requirements, and advanced signal integrity needs. We support applications from concept through to high-volume production.

Strategic Sourcing & Buyer Confidence

Supply Chain & Cost Advantages

Value-Added Engineering

Buyers appreciate our attention to compliance, traceability, and cost-saving opportunities without compromising on quality. Whether you manage prototype builds or global sourcing programs, our team aligns with your business model.

Sustainability in Harness Design

We help clients meet their ESG (Environmental, Social, and Governance) goals by embedding sustainability into every stage of harness development:

RoHS and REACH-compliant components – Ensuring every part meets global standards for hazardous substance control and chemical safety.

Optimized routing and layout design – Reducing wire lengths and material usage without affecting electrical performance.

Energy-efficient production practices – Implementing power-saving equipment, LED-based work cells, and lean assembly lines.

Closed-loop recycling systems – Collecting and reprocessing wire scrap and insulation trimmings into reusable materials.

Modular reusability across harness platforms – Designing with standardization in mind, allowing sub-harness reuse across SKUs and product lines.

Digital documentation – Reducing paper waste and improving lifecycle traceability for green compliance audits.

Eco-friendly packaging and shipping – Using recyclable packaging, right-sized cartons, and carbon-efficient logistics planning.

Our design philosophy supports both product performance and long-term environmental stewardship. Celestix proves that sustainable manufacturing can coexist with high-reliability, mission-critical solutions.

Trusted by Engineers, Powered by Experience

Our partnerships span OEMs, contract manufacturers, and global tier suppliers. Celestix becomes an extension of your engineering team, offering design insights and manufacturing scalability.

Let’s Co-Engineer the Future

Seamless integration starts with collaborative harness design.

Are you:

An OEM scaling EV or automation?

A sourcing lead under pressure to cut risk and cost?

A design engineer with complex needs?

Let’s talk:

info@celestixindustries.com

Celestix — engineered for performance, optimized for trust.