The #1 Mistake OEMs Make When Sourcing Wire Harnesses—and How to Avoid It

When it comes to OEM wire harness procurement, the decisions made during sourcing can have a significant impact on product reliability, compliance, and cost. In today’s fast-paced manufacturing world, OEMs rely on wiring harnesses as the central nervous system of their systems—from electric vehicles to industrial robots. However, one error surfaces time and again across sectors like automotive, aerospace, medical, and industrial automation:

1. Prioritizing Price Over Process Integrity

This is the top mistake in harness procurement. On the surface, choosing the lowest quote appears cost-effective. But the reality is more costly: wire harness sourcing mistakes like skipping quality checks, using substandard materials, or cutting corners in crimping and testing often result in operational delays, non-compliance, and product failures.

OEMs who underestimate the complexity of harness engineering and quality assurance often fall victim to sourcing pitfalls that compromise safety, performance, and their brand reputation. Let’s break down the problem—and the solution.

2. Common OEM Sourcing Mistakes

Here are the most frequent sourcing errors that OEMs commit:

Ignoring wire harness supplier risks in favor of lower prices

Selecting vendors without proper wire harness certifications (e.g., IPC/WHMA-A-620, IATF 16949)

Underestimating environmental or mechanical stress testing

Overlooking the total cost of ownership (TCO)

Not conducting supplier audits or managing sourcing risk

Failing to prototype or test for compliance and durability

Choosing non-compliant vendors in regulated industries (e.g., aerospace, EVs, medical)

These errors can lead to production delays, field failures, costly recalls, and irreparable damage to brand trust.

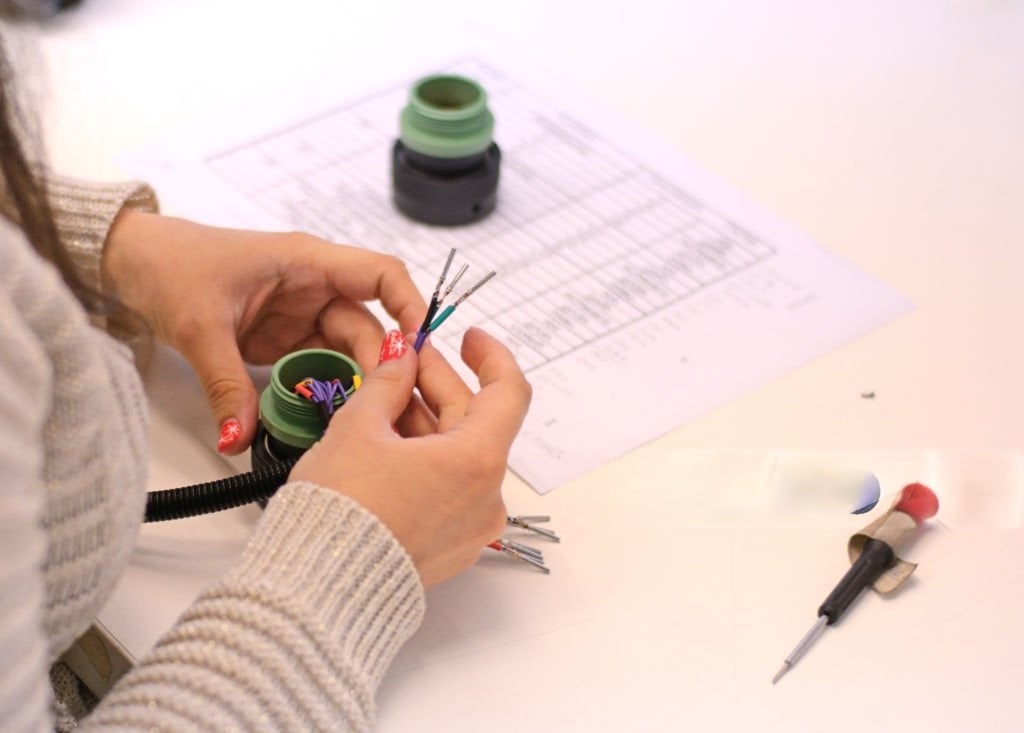

3. Why OEMs Must Choose Process-Focused Wire Harness Suppliers

At Celestix Industries, we address the biggest error in wire harness buying by building every solution on a foundation of quality control, certification, and traceability. Whether you're sourcing for automotive, industrial automation, or consumer electronics, our engineering-first approach prevents the most common harness manufacturing defects and compliance issues.

Our Approach Includes:

Use of certified materials (e.g., PVC, Teflon, braided sleeving)

Conducting 100% testing:

Continuity

Hi-Pot

Pull force

Crimp cross-section

Rapid prototyping and design validation

Over-molding and EMI shielding

In-house lab and IPC-certified operators

We also help OEMs avoid:

Wire harness quality control errors

Custom harness design errors

EV wire harness procurement pitfalls

Automotive harness sourcing risks

Medical device harness failures

4. Real-World Case: Avoiding EV Harness Procurement Pitfalls

Problem:

EV startup experienced overheating during fast charging

EMI issues disrupted the BMS

Supplier failed Hi-Pot and continuity tests

Celestix Solution:

Aluminum-copper hybrid conductors

Braided EMI shielding

Over-molded, IP67 connectors

Full lifecycle testing

Results:

20% faster charge time

Zero validation failures

Boosted range and safety compliance

This project demonstrated how the right wire harness supplier selection can transform risk into reliability.

5. Best Practices for Wire Harness Sourcing

To avoid sourcing pitfalls and delays, follow these best practices:

5.1 Certification and Compliance

5.2 Strategic Sourcing Steps

Audit supplier infrastructure

Evaluate technical capabilities

Review documentation and traceability

Request testing protocols and compliance history

Ensure capacity scalability (5x production scale-up)

Assess their ERP and change control process

Following these steps reduces OEM sourcing mistakes and strengthens long-term partnerships.

6. Sourcing Custom Wire Harnesses: Key Questions

Ask the following to evaluate fit:

What tools and platforms are used for CAD and prototyping?

How do you manage lead times and long-lead components?

Are alternate materials suggested with equivalent specs?

Do you offer FA approval or PPAP submission?

What failure rate benchmarks do you follow?

What is your lot traceability and recall response plan?

These questions help OEMs navigate complexity in wire harness buying and improve procurement psychology through informed decision-making.

7. Final Thought: Precision Sourcing Protects Performance

Wire harnesses are the unsung heroes of product performance. A great design fails without the right electrical backbone. The cost-saving mistakes OEMs make during sourcing can sabotage the integrity of entire systems.

But the reverse is also true: by avoiding harness sourcing mistakes and choosing suppliers with the right mix of engineering skill, process integrity, and compliance, you protect your timelines, reputation, and customers.

Celestix Industries delivers end-to-end harness manufacturing with a focus on quality, flexibility, and technical depth.

8. Call to Action: Let’s Build It Right, Together

If you're ready to eliminate sourcing risks and partner with a manufacturer who prioritizes quality, responsiveness, and scale, we’re here to help.

Contact Celestix Industries today:

Have a design or need expert engineering guidance? Email us at info@celestixindustries.com

Want a detailed quotation? Share your specifications via our Request a Quote form

Need help choosing between material options, connectors, or insulation types? We assist with application-specific design decisions.

Require support for prototype builds or PPAP documentation? Our team offers both technical and regulatory expertise.

Managing tight timelines or scaling up production? Discover how we deliver 5–6x output capacity with uncompromised quality.

Prefer to speak directly? Reach our sourcing team via the Contact Us page.

Reliable. Responsive. Ready to Scale. That’s Celestix.