The Hidden Hero of Every Appliance: Wiring Harnesses That Last

When people think of appliances—whether a refrigerator, washing machine, or air conditioner—they usually focus on motors, compressors, or circuit boards. But there’s one unsung component that silently powers and connects every function: the wiring harness. Without it, power distribution and signal transmission can’t reach their destinations—and the appliance simply won’t work.

At Celestix Industries India Pvt. Ltd., we don’t just manufacture wiring harnesses—we engineer reliability with a focus on durability, design for manufacturability, and risk mitigation.

What Is a Wiring Harness?

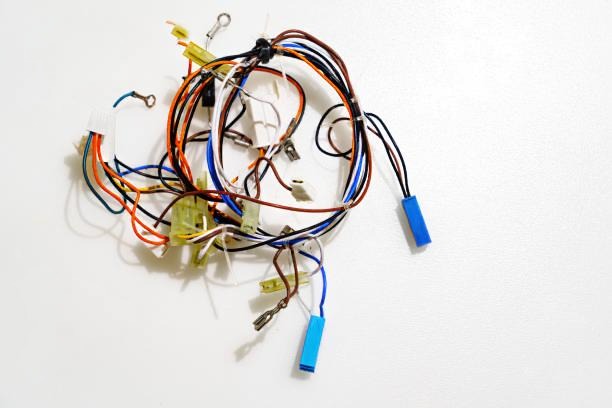

A wiring harness is a structured assembly of insulated copper conductors, connectors, terminals, and protective sheathing such as PVC insulation or PTFE sheathing, designed to route electrical power and signals through an appliance. Instead of individual wires, a harness bundles everything into a single, organized unit. This setup enhances performance longevity, minimizes errors, and ensures maintenance-free operation.

Just like a nervous system in the human body transmits signals and coordinates actions, the wiring harness delivers commands from control modules to motors, sensors, and displays—ensuring every feature of your appliance performs as intended. This hidden component is essential to electrical connections in every application.

Benefits of Wiring Harnesses

Simplified Wire Management – Bundling wires reduces clutter and simplifies routing.

Faster Assembly and Installation – Pre-assembled harnesses lower labor time and increase productivity.

Reduced Maintenance – Proper insulation and secure connections lead to fewer service issues.

Enhanced Electrical Reliability – Shielded and tested harnesses ensure stable power and signal flow.

Improved Environmental Durability – Materials like PTFE and silicone resist heat, moisture, and chemicals.

Higher Strain Relief and Physical Stability – Harnesses protect against vibration, pulling, and flexing.

Design Consistency – Standardized components reduce variability and error in high-volume production.

Better Safety and Compliance – Built to global safety and environmental standards.

Compact Designs – Saves space inside the appliance, crucial for compact and modular layouts.

Scalability for Automation – Compatible with robotic and semi-automated assembly processes.

At Celestix, we supply appliance wiring harnesses for nearly every major home device, including:

Refrigerators (smart, inverter, frost-free)

Washing machines and dryers

Microwaves and ovens

Dishwashers and freezers

Air conditioners and heaters

Vacuum cleaners, TVs, and sound systems

We also support customers in:

Consumer Electronics

Industrial Machinery

Medical Devices

EV Integration

Aerospace Applications

3.1. 100% Quality Testing and Control

Every harness undergoes:

Prototype testing to validate design assumptions.

Vibration testing to simulate real-world dynamic conditions.

Environmental durability testing (humidity, temperature cycles).

Electrical continuity and high-voltage tests to ensure reliable connections.

Crimping techniques verification using force and profile analysis.

Soldering method inspections to avoid cold joints.

Strain relief evaluation at stress points.

Failure prevention checks using accelerated aging simulations.

3.2. Certifications & Standards

We manufacture in compliance with:

All engineers are trained in IPC/WHMA-A-620, ensuring Class 3-level quality.

3.3. Smart Appliance Solutions

Project Example: Refrigerator Harness Optimization

Waterproof Connectors: IP67-rated, over-molded for zero condensation issues.

EMI Shielding: Braided shields eliminate interference in Wi-Fi modules and touchscreen panels.

High Temp Materials: Silicone wires improve compressor control and thermal safety.

Routing Optimization: Streamlined layout reduced 20% wire usage, speeding production by 15%.

3.4. Custom Design & Complex Applications

We offer:

Fully custom designs using CAD, digital twins, and virtual simulations.

High-voltage, shielded, and over-molded options tailored to the appliance environment.

Solutions for EVs, aerospace, industrial, and medical wiring needs.

Prototype-to-production support for small batches and global-scale orders.

3.5. Manufacturing Automation

Our advanced factory includes:

Robotic wire cutting and stripping for precision length and prep.

Ultrasonic welding for high-integrity joints without solder.

Automated labeling and barcoding for traceability and compliance.

Over-molding and plastic injection for plug durability and integration.

Conveyor-based layout assembly for repeatable accuracy.

Crimp force analysis systems for real-time validation.

Digital dashboards and ERP tracking for visibility and efficiency.

These practices support our commitment to operational excellence:

Just-in-time production ensures demand-driven delivery, minimizing excess inventory.

High flexibility and supply chain resilience allow us to adapt to shifting customer needs quickly.

Lower total cost of ownership through optimized processes and high-quality materials reduces long-term operating costs for our clients.

Our Engineering Approach

Our harnesses are designed based on the following principles:

Material Selection: Copper conductors, flame-retardant insulations (PVC, PTFE), abrasion-proof sleeves.

Design for Manufacturability (DFM): Layouts optimized for automation, reliability, and efficiency.

Failure Prevention: Crimp validation, tensile testing, thermal cycling, and humidity resistance.

Technical Expertise: IPC-certified engineers using modern design and testing tools.

Risk Mitigation: Alternate sourcing plans, inventory buffers, and early design feedback.

Summary Table: Why Choose Celestix

A Legacy of Essential Wiring

Since 2010, Celestix has delivered wiring solutions with proven reliability, durability, and longevity. We use only trusted materials and techniques, continuously investing in manufacturing automation, design innovation, and customer satisfaction.

With a focus on brand reputation, value proposition, and long-term buyer confidence, we proudly serve some of the world’s top OEMs.

Get in Touch

If you’re an appliance manufacturer seeking a long-term partner for reliable, certified, and future-ready wiring harnesses:

Email: info@celestixindustries.com

Request a Quote: Get a Quote

Contact Us: Contact Form