The Role of 3D CAD in Wire Harness Design: Best Practices

Why 3D CAD Is Revolutionizing Wire Harness Engineering

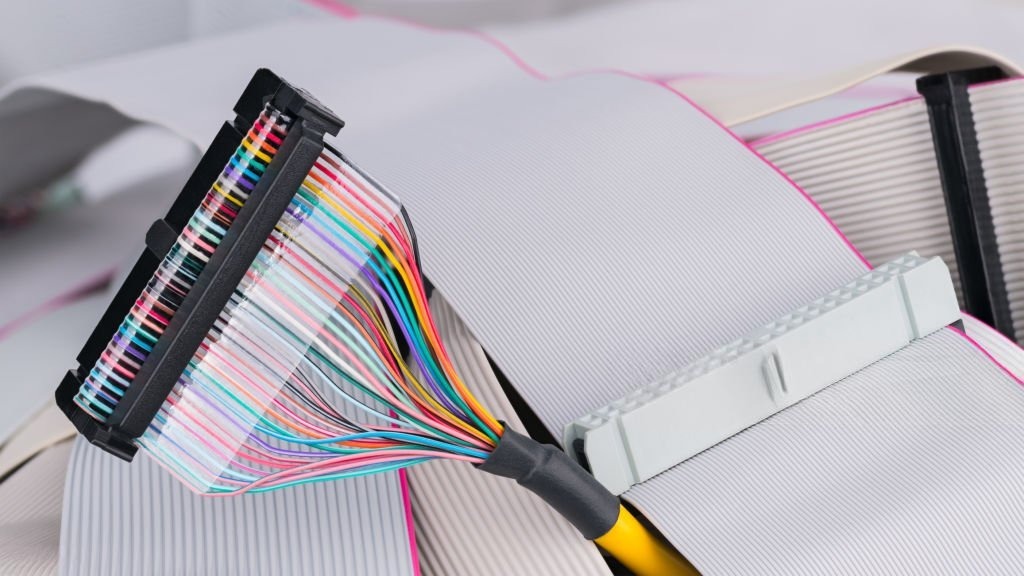

Wire harnesses are no longer simple assemblies of wires—they are precision-engineered systems vital to the performance of today’s vehicles, machines, appliances, and devices. For automotive, industrial automation, medical equipment, aerospace, telecommunications, and consumer electronics, complexity is rising fast. To meet that demand with accuracy and efficiency, 3D CAD for wiring harness design has become indispensable.

At Celestix Industries, a leading custom wiring harness manufacturer based in Pune, India, we embed wiring harness CAD software into every phase of our wire harness engineering process. This article outlines why 3D CAD wire harness design is critical—and the best practices in wire harness design Celestix follows to ensure every harness is built right the first time.

Introduction to 3D CAD in Harness Design

Traditional 2D drafting often lacks the spatial fidelity needed for routing wires around complex mechanical geometries. 3D CAD software for harness design—like Siemens NX wire harness, EPLAN Harness proD, Cadonix Arcadia wiring, TE HarnWare design, RapidHarness CAD tools, VeSys harness design, and HarnesSYS 3D modeling—solves this by allowing:

Wire harness routing CAD within actual 3D environments

Real-time bend radius calculations and voltage drop simulation CAD

Connector design 3D CAD validation and strain relief optimization

Export-ready BOMs, cut lists, and digital twin harness models

Unlike 2D drawings that may require multiple revisions, wire harness 3D modeling identifies conflicts early, reducing costly rework and enabling virtual prototyping wire harness workflows.

At Celestix, our engineering team uses CAD tools to accelerate both wire harness prototyping and large-scale production.

Why It Matters: Industry Demands Are Changing

Modern electrical harness design must now accommodate:

Automotive wire harness design for EVs, hybrid vehicles, and ADAS systems

Aerospace wire harness CAD for lightweight and extreme reliability

EMI-sensitive circuits require an EMI shielding wire harness design

Thermal analysis wire harness validation for power electronics

IP67 connector CAD modeling for waterproof, dustproof durability

Compliance with wire harness design standards such as IPC/WHMA-A-620 design and ISO 16750-4 harness testing

Quantified Impact of Late-Stage Errors

3D CAD harness optimization prevents these issues at the digital design stage.

Celestix’s CAD-Centric Best Practices

1. Design for Manufacturability Harness (DFMA)

We integrate DFMA wire harness design to ensure manufacturability and scalability:

Modular wire harness design for ease of assembly

Poka-yoke harness design to eliminate human error

Wire harness material selection using CAD simulations

Copper vs aluminum harness trade-off studies for cost and weight

Insulation materials CAD validation for thermal and chemical resistance

Material Comparison Table:

2. Real-World Geometry Simulation

We simulate real-world constraints with 3D CAD digital twin harness models:

Bend radius compliance

EMI-safe routing

Strain relief optimized using strain relief CAD design

Serviceability improvements for long-term reliability

3. Wire Harness Simulation CAD

Our engineers run advanced simulations:

Voltage drop simulation CAD for high-voltage harnesses

Thermal analysis wire harness for heat-intensive applications

Wire harness failure analysis under stress cycles

EMI shielding effectiveness in automotive wire harness design

4. Documentation and Standardization

We enforce 3D CAD harness standardization:

Traceable BOMs for OEM audits

Automated compliance reports

Wiring harness cost reduction through design optimization

Support for wire harness assembly automation

5. Collaboration and Automation

Using 3D CAD collaboration tools, we:

Co-design with OEMs and suppliers

Accelerate prototyping with virtual prototyping wire harness workflows

Integrate supplier inputs with supplier collaboration CAD design

Engineering Advantages of 3D CAD for Wire Harnesses

Industry Use Case: EV Battery Harness Design

Celestix engineered an electric vehicle wiring design for a next-gen SUV:

Applied CAD tools for EV harness validation

Optimized copper vs aluminum harness layouts for weight reduction

Modeled EMI shielding wire harness to protect powertrain systems

Validated with voltage drop simulation, CAD, and thermal analysis wire harness

Results:

20% charging time reduction

15% weight savings with aluminum-copper hybrids

Compliance with ISO 6722, IEC 60228, and IPC/WHMA-A-620 design standards

Faster OEM integration with 3D CAD digital twin harness deliverables

Extended Applications of 3D CAD in Wire Harness Engineering

Beyond EVs, 3D CAD enhances wire harness engineering across industries:

Aerospace harness reliability achieved with aerospace wire harness CAD

Defense harnesses validated with wire harness failure analysis

Telecommunications harnesses built with 3D CAD harness optimization

Renewable energy wiring tested with thermal analysis wire harness models

Heavy equipment wiring enhanced with wire harness assembly automation

Extended Sector-Specific Benefits

How 3D CAD Supports Multiple Industries

Automotive Wiring Harness: EV-ready, EMI-shielded, and lightweight designs

Industrial Automation: Modular harnesses for robotics and heavy machinery

Medical Equipment: Compact, high-reliability assemblies for diagnostic devices

Consumer Electronics: Overmolded harnesses for smart appliances

Defense & Aerospace: Mission-critical aerospace wire harness CAD with redundant safety designs

Renewables: Long-life, outdoor-rated harnesses for solar and wind systems

Why Celestix Excels in CAD-Based Harness Engineering

100% QC at every stage

Certified: ISO 9001, IATF 16949, RoHS, CE, UL

Expertise in DFMA wire harness design and wire harness automation design

Advanced simulation with wire harness simulation CAD for EMI, thermal, and voltage drop

In-house validation under ISO 16750-4 harness testing

Full compliance with IPC/WHMA-A-620 design standards

Scalable manufacturing: 5–6x capacity increase on demand

Global supply network with customer-first responsiveness

Closing Thoughts: CAD as a Catalyst for Reliability

3D CAD wire harness engineering is not just a design tool—it is a best practices wire harness design framework. From connector design 3D CAD to wire harness prototyping and wire harness automation design, Celestix integrates every step for performance, compliance, and speed.

By leveraging advanced CAD platforms such as Siemens NX wire harness, EPLAN Harness proD, Cadonix Arcadia wiring, TE HarnWare design, RapidHarness CAD tools, VeSys harness design, and HarnesSYS 3D modeling, Celestix delivers wiring solutions that empower OEMs to innovate with confidence.

Whether you're building the next-gen EV, advancing aerospace technologies, or upgrading industrial automation systems, Celestix Industries is your trusted partner in 3D CAD harness optimization.

Let’s collaborate.

Get a quote tailored to your harness requirements:

Request a Quote

Or contact us directly:

info@celestixindustries.com

Ready to Start Your Next Project?

At Celestix Industries, we help OEMs and global manufacturers accelerate time-to-market with precision-engineered harness solutions. Whether you need prototyping, EV wiring harness design, or aerospace-certified assemblies, our engineering team is ready to collaborate.

Contact us at info@celestixindustries.com

Submit your requirements via Contact Form

Get fast pricing and lead time estimates through our Quote Request

Celestix Industries – Engineering Reliability, Powered by 3D CAD.