Why IPC/WHMA-A-620 Compliance Is Non-Negotiable in Automotive Wiring Harness Manufacturing

Summary: As vehicles become more software-defined and electrically complex, wiring harness reliability is critical. This article explores why IPC/WHMA-A-620 Class 3 compliance is essential in automotive applications, how it reduces failure risks, and how manufacturers like Celestix Industries ensure quality, traceability, and scalability.

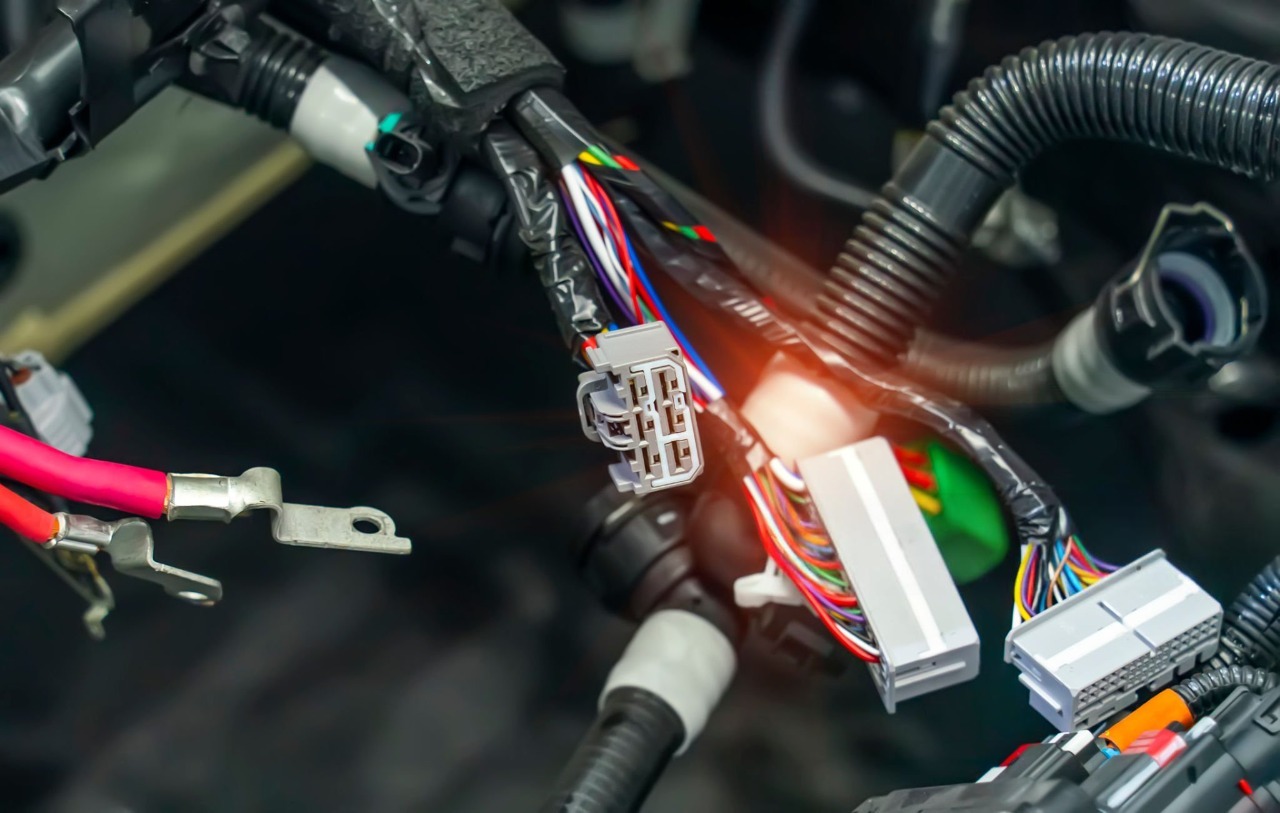

1. Wiring Harnesses: The Automotive Nervous System

Modern vehicles—primarily electric and autonomous ones—can contain over 5 kilometers of wire and more than 100 ECUs. From powering the drivetrain and sensors to enabling infotainment and driver-assist features, the wiring harness acts as the vehicle’s central nervous system.

Without robust and reliable electrical connectivity, vehicles are reduced to inert frames. As digital control systems become more sophisticated, the demands placed on wiring harness reliability and signal integrity increase exponentially.

Common Wiring Harness Risks in Automotive Applications:

2. What is IPC/WHMA-A-620?

The IPC/WHMA-A-620 standard, jointly developed by IPC and the Wire Harness Manufacturers Association, defines minimum acceptability requirements for cable and wire harness assemblies. It is widely adopted across industries where safety, performance, and durability are non-negotiable.

Key Components Covered by IPC/WHMA-A-620:

Crimping techniques and height tolerances

Solder joint integrity

Acceptable levels of contact resistance

Wire insulation strip lengths

Routing, bundling, and strain relief

Environmental shielding (moisture, abrasion, EMI)

Heat shrink usage and positioning

Comparison Table: IPC Workmanship Classes

At Celestix, every automotive wiring harness is manufactured to Class 3 standards—ensuring superior performance even in the most extreme vehicle operating conditions.

3. The Automotive Sector Demands Class 3 Rigor

Automotive harnesses operate in extreme conditions:

Temperature Range: -40°C to +150°C

Vibration Exposure: Chassis and powertrain environments

Voltage Range: Up to 800V in EV systems

Class 3 Wiring Harness Features:

High current carrying capacity

Secure terminal crimping with consistent pull strength

Moisture resistance and thermal stability

Long-term mechanical integrity

Tolerance to flexing and abrasion over thousands of cycles

At our advanced wire harness manufacturing facility in India, Celestix performs rigorous lifecycle simulations to guarantee reliability from factory floor to finished vehicle.

4. The Hidden Risks of Non-Compliance

Ignoring IPC/WHMA-A-620 compliance introduces several critical risks:

Increased Field Failures

Expensive Warranty Claims & Recalls

Regulatory Non-Compliance (e.g., ISO 26262, FMVSS 106)

Loss of OEM Contracts

Compromised Safety Systems (airbags, ABS, lane assist)

Even minor deviations can result in functional degradation under high-heat, high-vibration, or chemical exposure environments—common across EV platforms.

5. Quality, Repeatability, and Traceability

At Celestix, every wiring harness goes through rigorous validation:

Quality Measures Implemented:

100% continuity and high-voltage testing

Pull-force and crimp cross-section verification

Environmental simulations (humidity, vibration, thermal cycling)

Traceable part and process documentation

AOI (automated optical inspection) for connector placement

Barcode-based harness tracking and batch history

Example Traceability Report:

6. Compliance as a Competitive Advantage

Celestix isn’t just a vendor. As a custom wiring harness manufacturer with global clients and a reputation for consistency, we treat IPC/WHMA-A-620 certification as the floor, not the ceiling.

Real-World Use Case: Automotive OEM in Europe

A leading electric vehicle manufacturer based in Germany experienced repeated signal loss in its battery management systems due to poor terminal crimps from a non-compliant supplier. After switching to Celestix Industries, which manufactures all harnesses to IPC/WHMA-A-620 Class 3 standards, the OEM saw:

72% reduction in field failures over 12 months

Zero warranty claims related to wiring harnesses

Streamlined compliance audits for IATF 16949 and CE

Core Advantages for Automotive Clients:

Bulletproof quality systems

International regulatory readiness

Documented failure-proofing

Seamless integration into advanced vehicle platforms

Confidence in sourcing from a traceable, disciplined supplier

Our facility in Pune, India, supports:

Flexible low- or high-volume programs

In-house lab and overmolding capabilities

100% in-process and final QC

Scalability (5–6x annual production ramp-up)

Final Word: Build with Confidence

IPC/WHMA-A-620 compliance is not a checkbox. It’s the foundation of trust in every critical circuit, connector, and cable. And it’s the standard by which Celestix Industries builds every automotive wiring harness.

Ready to upgrade your harness sourcing strategy with a proven wire harness manufacturing partner?

Reach out to Celestix today:

info@celestixindustries.com

Let’s engineer reliability, together.