Why IPC/WHMA‑A‑620 Defines the Future Standard for Wiring Harness Quality – Celestix Industries

Introduction

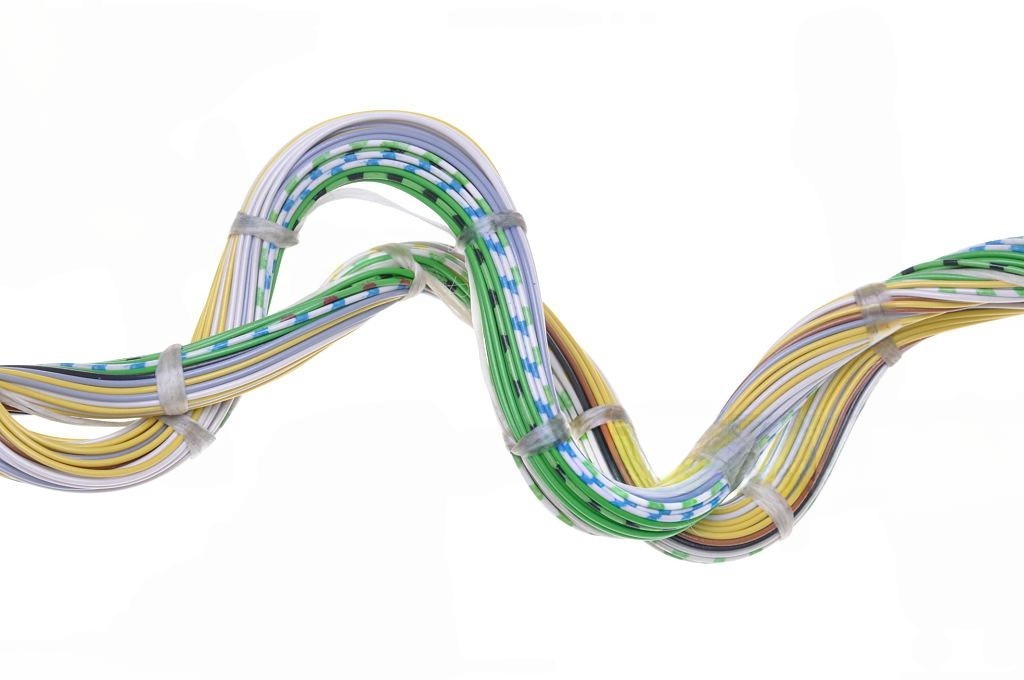

In an era of electrification and automation, wiring harnesses and cable assemblies serve as the critical backbone of industries ranging from automotive and aerospace to medical devices, telecommunications, and industrial equipment. At Celestix Industries India Pvt. Ltd., we understand that safety, precision, and reliability are non-negotiable. That’s why our engineers and operators are trained and certified to comply with IPC/WHMA‑A‑620 – the global benchmark for wiring harness assembly excellence. This standard doesn’t just shape how we manufacture – it defines how we lead.

1. The Global Benchmark in Harness Quality

IPC/WHMA‑A‑620 Revision E is the only industry-consensus standard for acceptance criteria in wire and cable harnesses. Recognized worldwide, it aligns expectations across OEMs, Tier-1 suppliers, and quality assurance teams.

Why Celestix Complies:

Ensures seamless collaboration with global clients

Eliminates ambiguity in inspection and validation

Reinforces our commitment to zero-defect delivery

For OEMs, this means fewer disputes and higher trust. For Celestix, it means upholding our reputation as a certified, reliable manufacturer.

2. Exhaustive Requirements – Visual, Technical, and Tested

Revision E includes 388 comprehensive pages across 19 sections, featuring over 700 high-resolution visual references — each designed to ensure visual consistency, technical correctness, and field durability.

At Celestix, we implement:

Crimp force analysis and pull testing after every setup change

Soldering, splicing, securing, and routing inspections

High-voltage, flex, and temperature cycling tests for harsh environments

Our in-house lab and fully trained IPC-certified teams guarantee assemblies meet every requirement of Class 1 to Class 3 workmanship.

3. Class 1, 2, and 3: Risk-Based, Application-Aligned

Celestix delivers wiring harnesses tailored to application-criticality:

Class 1 – General Products: Home appliances, consumer electronics

Class 2 – Dedicated Service: Industrial controls, telecom systems

Class 3 – High-Reliability: Aerospace, medical devices, military-grade harnesses

Each harness we ship is inspected for class-specific quality, and we maintain full traceability — from wire to final assembly.

4. Measurable Quality, Operational Excellence

With IPC/WHMA‑A‑620 at the core, our clients experience:

DPPM reduction through visual and functional inspection

Faster throughput due to standard-driven visual cues

Compliance assurance for CE, UL, IATF 16949, RoHS, REACH, and more

Case in Point:

Our Class 3 certified harnesses helped a global EV manufacturer resolve voltage drops, EMI interference, and thermal failures — reducing warranty claims by 40% and increasing power efficiency by 8%.

5. IPC Certification Builds a Skilled Workforce

Every Celestix operator undergoes IPC/WHMA‑A‑620 training, and we provide continuous process improvement through:

In-house crimp cross-section analysis

Certifications for operators, inspectors, and trainers

Ongoing audits, process standardization, and documentation control

OEMs trust certified teams. Celestix delivers them — ready, compliant, and capable.

6. Built for Tomorrow’s Demands

The IPC/WHMA‑A‑620 framework evolves to support:

Automation integration (robotic crimping, ultrasonic welding)

Lightweight designs (for EV and aerospace platforms)

Smart harnesses (IoT sensors, predictive analytics)

Sustainable manufacturing (RoHS/REACH compliant materials)

At Celestix, we’re investing in E-Beam wire prep, AI-driven inspection, and digital twins for pre-production simulation, making us future-ready today.

Benefits Summary: Why It Matters

Final Thoughts

IPC/WHMA‑A‑620 is more than a standard — it’s a strategic investment in quality, trust, and future-readiness. At Celestix Industries, it’s part of our DNA. Whether we’re delivering automotive engine harnesses, over-molded connectors for smart appliances, or shielded cable assemblies for medical robotics, we build to this gold standard.

Partner with a team that doesn’t just follow compliance — but leads with it.

Ready to elevate your harness quality?

Or email: info@celestixindustries.com