Wiring Harness Design for Autonomous Vehicles: What’s Changing?

As autonomous vehicle (AV) technologies race ahead, the complexity under the hood is rapidly transforming—particularly in one critical area: wiring harness design. At Celestix Industries, we’re not just keeping pace—we’re helping lead the evolution.

The future of mobility is electric, intelligent, and autonomous. To power that future, wiring systems must evolve from passive conduits to smart, integrated networks. Celestix has engineered that evolution into every wire, terminal, and connector we produce.

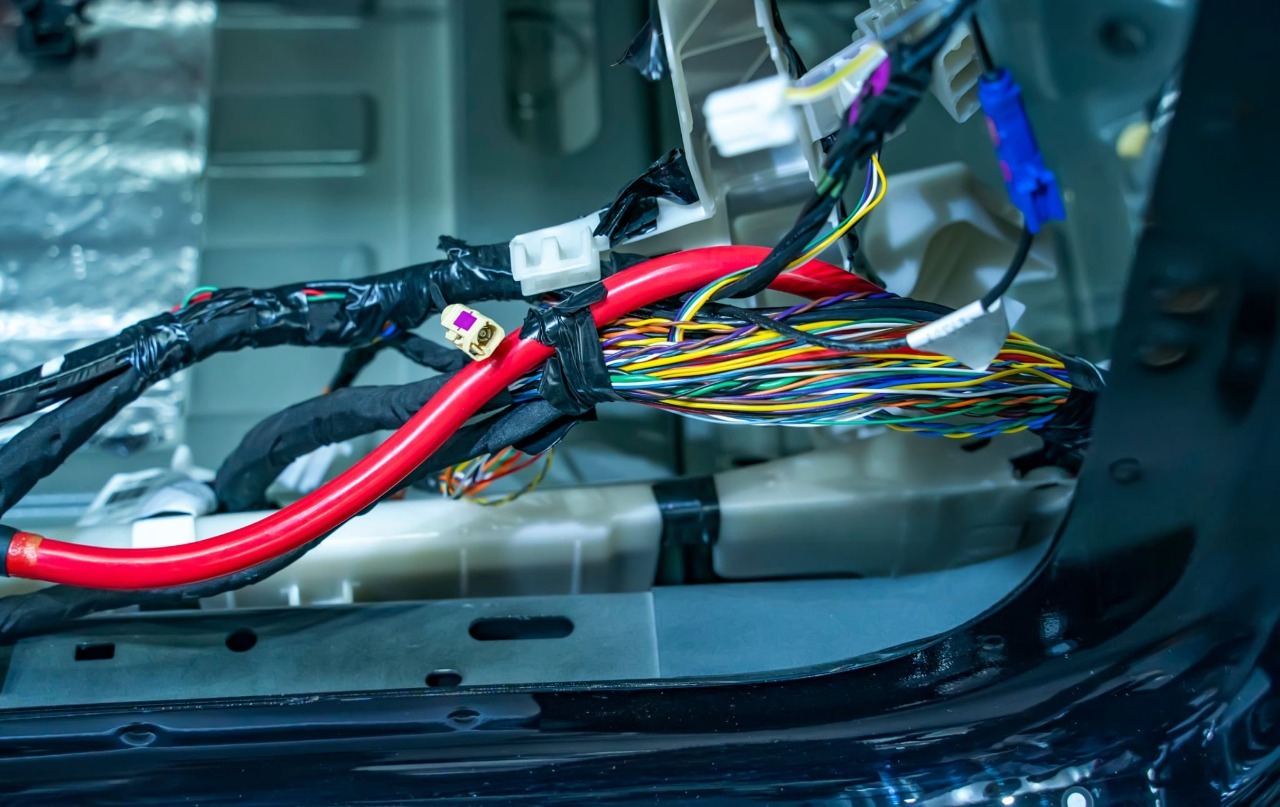

This transformation touches every aspect of wiring design: from lightweight wiring harness design for EVs, to modular wiring harness for AVs, to advanced sensor wiring harnesses for ADAS systems. These systems must support V2X communication, infotainment, battery management, and predictive maintenance—all while meeting the stringent standards of IPC/WHMA-A-620 and AS9100 for safety and reliability.

Autonomous vehicles also bring new challenges in spatial dynamics, requiring ultra-small diameter wiring that doesn't compromise on data integrity or heat dissipation. The role of the wiring harness has evolved beyond passive connectivity; it is now a central nervous system that interacts with AI, machine learning modules, and edge computing devices in real time.

In addition, the demand for scalability and interoperability across platforms makes it crucial that harnesses adapt to both hardware and software-defined vehicle architectures. This means integrating diagnostics, remote firmware upgrade compatibility, and power/data multiplexing into the harness design.

Harnessing innovations in smart wiring harness technology, Celestix delivers solutions that adapt to ever-tightening safety standards, power demands, and communication protocols of tomorrow's autonomous and electric mobility.

The Shift: From Simple Power Loops to Intelligent Data Backbones

Modern autonomous and electric vehicles require:

High-speed data transmission wiring harnesses for LiDAR, radar, and AI processors

Fiber optics in automotive wiring for high-bandwidth communication

CAN bus wiring harness design for system integration

Redundant, waterproof terminals for enhanced safety

Vibration-resistant wiring harnesses for rugged terrain

Thermal management wiring harnesses to control heat from power electronics

Low-latency harnesses for real-time system feedback

Wiring harness traceability standards to meet compliance and maintenance requirements

Table 1: Key Wiring Requirements for Autonomous Vehicles

Additionally, our teams validate interoperability of these harnesses with automotive-grade chipsets, communication modules, and thermal management subsystems through simulation and real-world testing protocols. We go beyond routine validation, incorporating use-case simulations that anticipate stress behavior in real environments such as extreme weather, high vibration zones, and long-cycle operations typical of autonomous fleets.

Driving Factors Behind the New AV Harness Design Paradigm

AV System Complexity

The rise of multi-ECU and AI-driven systems requires a dense, shielded harness architecture

Digital twin wiring harness design used to simulate thermal/electrical loads

Harnesses now require built-in support for diagnostic feedback and modular fault isolation

Modular and Scalable Platforms

Multi-variant vehicle architectures benefit from plug-and-play modular harnesses

Reduced tooling costs and easier harness upgrades in successive vehicle models

Common connector interfaces reduce supplier dependencies and simplify global rollout

Design Innovation for EVs

High-efficiency copper-aluminum hybrid conductors for better current-carrying capacity

Reduced-loss high-voltage wiring harnesses with robust insulation

Enhanced EMI protection around the battery management system

Sealed interconnects for charger inlets and battery distribution units

Autonomous Driving Requirements

EMI-resistant harnesses for ADAS and autonomous driving computers

Real-time feedback loops enabled by sensor wiring harnesses

High durability to withstand vibration, shock, and environmental stressors

Integrated isolation for safety-critical functions (brakes, steering, suspension)

Efficiency and Cost Optimization

Automated cutting, stripping, and crimping processes reduce labor and error rates

Harness designs validated through Harness Builder E3.series and Siemens Capital to control BOM costs

Use of digital threads for manufacturing traceability and quick defect resolution

LEAN and Six Sigma methodologies integrated into wire production and assembly

Next-Gen Applications and Emerging Trends

Celestix AV harness capabilities include:

Radar and LiDAR wiring harnesses designed for signal fidelity and isolation

Battery management wiring harnesses for EVs with integrated temperature sensors

Shielded USB, CAN, and Ethernet harnesses for infotainment systems

Multi-connector layouts for V2X communication nodes and edge devices

Low-latency wiring harnesses supporting AI-based decision-making modules

Enhanced EMI shielding to meet ISO and UL safety benchmarks

Software-defined architecture harnesses for over-the-air update support

Harnesses that conform to functional safety (ISO 26262) and cybersecurity (UN R155) norms

Interoperability with digital infrastructure for connected cars and smart cities

Future-Proofing with Smart Materials and Sustainability

Celestix invests in forward-looking technologies such as:

Smart materials that adjust conductivity and thermal characteristics based on load

Environmentally compliant materials that support green manufacturing initiatives

Built-in diagnostics for predictive maintenance wiring harnesses, integrated at both hardware and software levels, capable of reporting wear, resistance changes, or short circuits

Custom designs to meet wiring harness safety requirements for connected and autonomous vehicles

Halogen-free and low-smoke materials for cabin applications

Biodegradable wire insulation alternatives for reduced lifecycle impact

Packaging strategies that reduce waste and optimize part kitting for assembly lines

Our sustainable approach ensures compliance with global standards like RoHS, REACH, and ISO 14001, while reducing the carbon footprint of large-scale harness production.

Celestix: Solving the Wiring Harness Challenges of 2025 and Beyond

Our Differentiators:

Deep AV routing and architectural experience

Access to premium suppliers like Molex, TE, Amphenol

Integration-ready with Zuken E3.series, Siemens Capital, and Harness Builder tools

End-to-end validation: EMI shielding, thermal modeling, mechanical simulation

Lot-level serialization and traceability aligned with AS9100, ISO 26262, and IPC/WHMA-A-620

Engineering support from concept to PPAP and full-volume production

100% testing for continuity, hipot, and pull-force validation using high-end testers

Real-time dashboard monitoring and QR code-based cable traceability

Dedicated quality team for managing regulatory documentation, FAIs, and PPAPs

Product lifecycle support from development through obsolescence planning

Our R&D team actively explores applications of blockchain traceability, digital twin replication, and AI-assisted visual inspection to future-proof the harness production pipeline. Additionally, we collaborate with OEMs to conduct field data analytics on harness longevity and fault tolerance.

Explore our wiring harness solutions for autonomous and electric vehicles through our website, or connect with our team via the contact form or email to start your custom harness development. We invite OEMs, Tier-1s, and system designers to collaborate on building the next generation of connected mobility.

Celestix doesn’t just manufacture wiring harnesses. We engineer the nervous system of tomorrow’s mobility.