Wiring Harness Standards: The Global Compliance Framework Behind Celestix Manufacturing

Why This Matters Now

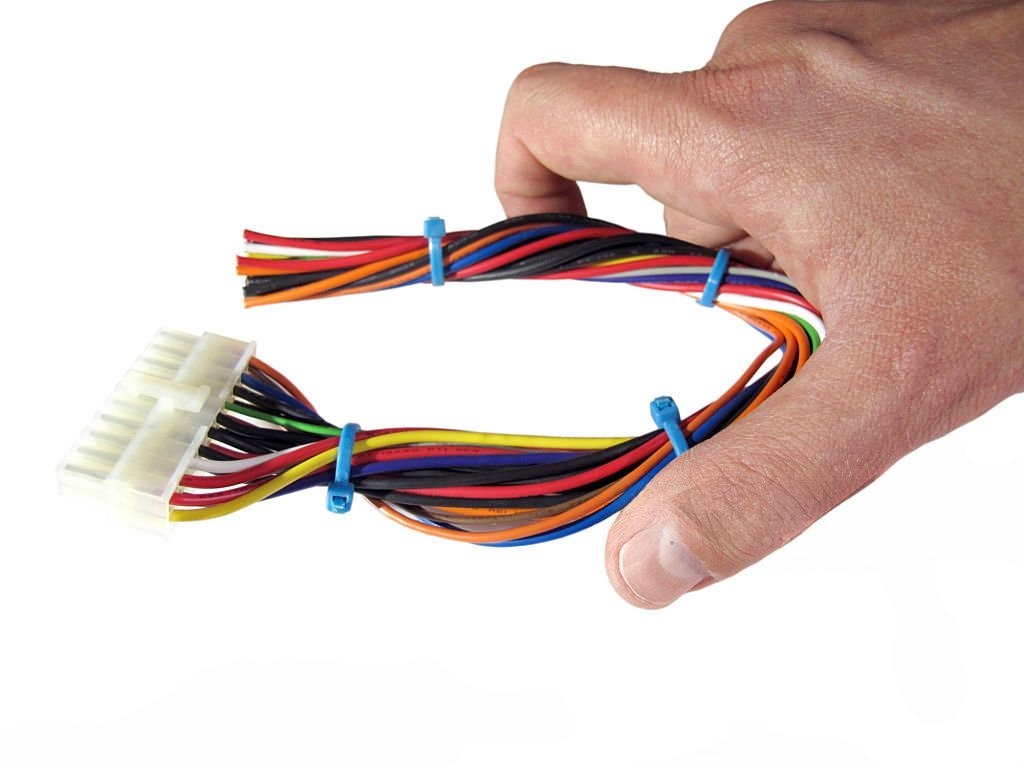

As industries advance in automation, electrification, and global regulatory alignment, adhering to recognized wiring harness standards is essential—not optional. Standards such as IPC/WHMA-A-620, ISO 9001, IATF 16949, and AS9100 wiring harness protocols are central to building safe, high-performing systems.

At Celestix Industries, we build more than products—we engineer compliance, precision, and longevity. From automotive wiring harness standards to medical ISO 13485 harnesses and MIL-DTL-3885G aerospace wiring, our certified harnesses are trusted across industries.

Companies that ignore compliance risk may experience production delays, failed audits, or in-field failures. By contrast, harnesses built to standard allow OEMs and Tier 1s to accelerate time-to-market, minimize warranty costs, and meet global export requirements.

Regulatory environments are tightening across the board—from India's BIS mandates to European REACH and CE requirements. Harnesses must not only perform reliably—they must also demonstrate full compliance across materials, testing methods, and traceability systems. As OEMs embrace digital transformation and product miniaturization, wiring harnesses must evolve to support increased complexity, lighter weights, and smarter diagnostics.

What Wiring Harness Standards Guarantee

Compliance standards deliver consistency, safety, and performance across every product we manufacture. Here’s how:

Wiring harness quality control – Ensures uniformity and minimizes defects across batches, using control plans, poka-yoke setups, and defect escalation matrices.

Electrical harness compliance – Aligns with global regulatory frameworks like ISO, IPC, and MIL, enabling cross-border approvals and export-readiness.

Reliability through testing – Validated through environmental, mechanical, and electrical tests, including salt spray, high-potential (HiPot), continuity, and vibration tests.

Procurement confidence – Offers buyers traceable, test-verified, and serial-numbered harnesses with accompanying certificates of conformance (CoC).

Reduced downtime – Ensures faster diagnostics, easier troubleshooting, and on-site replacements using standard connectors and layouts.

Modular design support – Enables OEMs to design for families of products without changing the core harness architecture.

Vendor prequalification – Meets the audit criteria for leading OEMs, Tier 1s, and defense contractors through IATF, ISO, and BIS accreditation.

Lower total cost of ownership (TCO) – Reduces long-term expenses by eliminating recurring quality issues, field failures, and costly rework through root-cause driven process control and FMEA.

Supply transparency – Digitally captures every stage from raw cable receipt to final torque signature and packing label.

Engineering reusability – Saves engineering time and cost with CAD-integrated wire routing libraries and DFMA-friendly design archives.

Additional Testing and Validation Standards

Beyond standard checks, Celestix wiring harnesses undergo extended validation based on application requirements:

HALT/HASS screening – Identifies weak points under accelerated stress for mission-critical applications.

IP68 waterproofing validation – Guarantees performance in submerged and high-humidity environments.

Salt fog/corrosion testing – Simulates marine and coastal exposures for defense, energy, and off-road sectors.

Continuity and HiPot testing – Confirms electrical path integrity and insulation resistance beyond design thresholds.

Strain relief and bend radius checks – Prevents fatigue-related failures in robotic and high-flex routing.

Comparative Overview of Key Wiring Harness Standards

Production Capabilities at Celestix

Celestix's infrastructure and execution capabilities go beyond compliance—they’re built for precision, scalability, and speed:

In-house lab – Tests for IPC, ISO, CE, UL, BIS, RoHS, and REACH compliance, including specialized insulation, conductor resistance, and flammability assessments.

Dedicated quality cells – Execute FAIs, LPAs, layered audits, and root cause investigations integrated into our QMS.

Operator training programs – Structured, recurrent training at all certification levels ensures operators maintain IPC/WHMA-A-620 and J-STD-001 credentials and pass monthly refreshers.

Digital QC systems – Integrated MES system records operator ID, inspection logs, camera-based visual inspection, and torque checks linked to barcode scans.

Flexible production lines – Reconfigurable stations support low-volume prototyping, batch runs, and ramp-up programs using quick-change tooling.

Prototype-to-production workflows – Rapid turnarounds with full DFM reviews, pilot lot validation, and tooling scalability built in.

Call to Action

Partner with Celestix Industries for compliant, high-reliability wiring harnesses engineered to global standards. Our products are trusted across automotive OEMs, EV innovators, defense contractors, and industrial automation leaders worldwide.

Request a quote: https://www.celestixindustries.com/GetaQuote

Email us: info@celestixindustries.com

Contact form: https://www.celestixindustries.com/contact-us

Celestix Industries – Engineering Precision. Delivering Compliance.